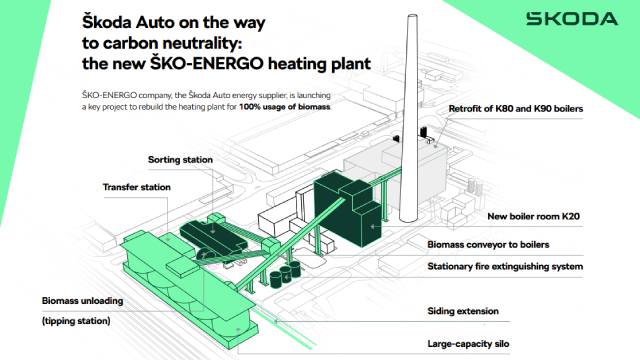

Biomass to produce green energy: the ŠKO-ENERGO power plant project

The power plant that supplies energy to the Mladá Boleslav site and heating for the city will switch to 100% biomass-based system, leading to a saving of up to 290,000 tons of CO2 per year.

Škoda continues its journey towards achieving carbon neutrality. It includes several milestones, and one of these involves the subsidiary ŠKO-ENERGO, which provides energy for the Škoda headquarters and heating for the city of Mladá Boleslav, in the Czech Republic.

ŠKO-ENERGO has launched a key project to upgrade its plant to run exclusively on biomass, specifically wood chips and phyto-pellets, thus becoming completely carbon neutral. The construction will begin in 2024 and the work will involve an investment of about 141 million euros; the new plant will be one of the largest of its kind in the Czech Republic and will be operational within three years. It will support Škoda in achieving its ambitious environmental targets along the entire value chain, as defined by the Next Level Škoda Strategy 2030.

Achieving Goals

"At Škoda Auto and ŠKO-ENERGO, we are very determined to achieve our ambitious sustainability goals: the transformation of the ŠKO-ENERGO plant represents the most radical modernization of the company's energy supplies in the last 25 years. It is also one of the largest industry projects in the Czech Republic, with estimated costs of more than 140 million euros, more than half of which will be covered by subsidies from the Czech Republic’s State Environmental Modernisation Fund. This impressively shows what we are able to achieve through close cooperation with our stakeholders" said Michael Oeljeklaus, Škoda Auto Board Member for Production and Logistics, and Chairman of the ŠKO-ENERGO Supervisory Board.

A three-year transformation

"Our existing heating plant already upholds modern standards and employs progressive technologies. ŠKO-ENERGO's strategy is to produce carbon-neutral energy, and the upgrade of the Mladá Boleslav power plant is crucial to this plan. After only three years from the start of the construction, both the manufacturing plant and households in Mladá Boleslav will have access to an eco-friendly heat source" added Tomáš Kubín, ŠKO-ENERGO’s Managing Director.

The project is scheduled to begin in the first half of 2024, and in three years the power plant will be totally renovated. All boilers will exclusively use biomass, consisting of 70% wood chips and 30% phyto-pellets. The Biomass will be certified according to European and Czech legislation, emphasising the sustainability of the entire supply chain. Once the transition is complete, annual CO2 savings will amount to an estimated 290,000 tonnes per year.

Towards Carbon Neutrality

ŠKO-ENERGO's power plant currently uses a combination of coal and biomass; the latter was introduced in 2005, and since then the proportion of eco-friendly fuel has been steadily increasing. By 2022, renewable energy sources accounted for about 35% of all energy used at Škoda Auto’s Czech production plants.

The Volkswagen Group brand has raised its environmental targets, reducing the carbon footprint of the company's operations even further. In its Czech and Indian plants, Škoda will transition to zero-emission production by the end of the decade, following the example of the Vrchlabí plant, which already achieved this milestone in 2020.

Towards Electric Mobility

On the product side, Škoda is significantly accelerating the introduction of new electric vehicles. Škoda will introduce six all-electric models in the coming years, with commitments to invest €5.6 billion into electromobility by 2027.

In addition, the Czech automaker is working to increase sustainability along the entire value chain. This includes extensive use of recycled and recyclable materials and the reuse of batteries from electric vehicles that have reached the end of their life cycle. Cars are disassembled and batteries are recovered, than they are used in stationary installations. The last stage is a very thorough recycling, allowing new batteries to be created from their raw materials.

Source: ŠKODA

VGI | Responsible OU: VP | Creation date: article date | Class 9.1