Å KODA: an important step for COâ‚‚-neutral production

The Czech plant in Vrchlabí has reduced its CO₂ emissions from 45,000 to 3,000 tonnes per year and will offset the remaining emissions through compensation measures.

The Vrchlabí component plant – where 3 million DSG gearboxes have been built since 2012 – is set to become the first ŠKODA CO₂-neutral production site in the world. The greatest carbon dioxide savings have been made by rigorously converting the factory to the use of renewable energies – reducing CO₂ emissions from an initial 45,000 tonnes per year to a current 3,000 tonnes. The remaining emissions will be offset through further compensation measures and the purchasing of CO₂ certificates.

“From the second half of this decade, we will exclusively be using CO₂-neutral energy to produce vehicles and components at our Czech sites. The Vrchlabí plant is set to become a global pioneer for ŠKODA in terms of sustainability and energy efficiency”, said Michael Oeljeklaus, ŠKODA Board Member for Production and Logistics.

Saving energy

Energy-saving measures have been key during the process of converting the Vrchlabí plant to CO₂-neutral production; through the renovation of the factory’s heating system alone, it was possible to reduce the annual energy consumption by 6,700 MWh (megawatt hours).

In early 2020, efforts were stepped up to reduce energy consumption and the plant is pursuing twelve projects that will save more than 2,000 MWh of thermal energy and almost 1,800 MWh of electricity. These include closing unused heating circuits and regulating air flow and room temperatures to save energy. In addition, the lighting in numerous areas of the factory premises has been linked to operating hours.

Alternative energies

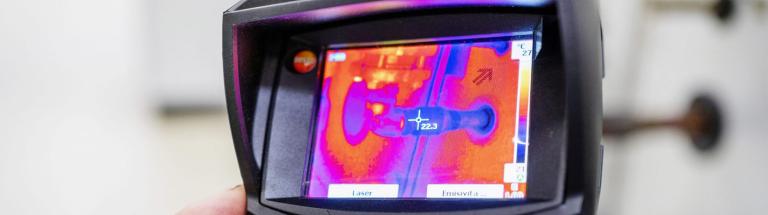

A thermal imaging camera is also used at Vrchlabí to detect heat loss not only around the building, but also within the heating system. By detecting this loss, it is possible to resolve leaks, thus saving heat and CO₂ emissions.

Alternative energies are also crucial in reducing emissions. 41,500 MWh of the 47,000 MWh of electricity required each year for production already come from renewable sources – that’s more than 88 per cent. Natural gas is the only remaining fossil fuel used. However, this will gradually be replaced by CO₂-neutral methane from biogas plants as of 2021.

Climate protection

The remaining unavoidable CO₂ emissions are to be offset through specific compensation measures and the purchase of CO₂ certificates. By obtaining these certificates, ŠKODA AUTO will be promoting climate protection projects such as renewable energy production in India or rainforest conservation.

Furthermore, ŠKODA is also encouraging environmental conservation initiatives within the company, such as planting almost 40,000 trees near the Vrchlabí site in 2020.

All-round sustainability

Sustainable investments are also being made at other sites throughout the world. The Pune factory in India commissioned one of the country’s largest solar-power rooftop systems at the end of 2019.

Biomass is also increasingly being used to generate electricity at the combined heat and power generation facility run by ŠKODA’s subsidiary ŠKO-ENERGO in Mladá Boleslav.

Source: ŠKODA