CO2-neutral by 2050: the Volkswagen Group's journey

To hit its targets (meeting the goals defined by the Paris Climate Agreement and becoming CO2-neutral by 2050), the Volkswagen Group is taking action on three fronts: reducing energy consumption, using renewable energy sources, and compensating unavoidable emissions.

The priority of the Volkswagen Group is its deep commitment to the climate targets laid out by the Paris agreement. “The climate crisis is the greatest challenge of our time. To mitigate its impact, it is imperative that we limit global warming,” explained CEO Herbert Diess.

“This is why the whole Group is to be CO₂-neutral by 2050 - this includes vehicles as well as plants and processes. We have a responsibility and an obligation to make our contribution to limiting climate change and working towards our goals with the utmost consistency. We have the opportunity and ability to do so.”

Carbon footprint

The Volkswagen Group is focusing on electromobility since battery-based vehicles have the best climate footprint of all drive systems over their entire service life. The range already includes electric vehicles, making electromobility mass market-compatible: the Volkswagen ID.31 e ID.42, for example, are both already carbon neutral.

Volkswagen’s battery production facilities use green electricity exclusively while the Group compensates any unavoidable emissions generated in supply chains and manufacturing processes by supporting climate projects.

Electric and future planning

By 2030, the Volkswagen Group will have brought to market 70 fully electric models – a total of 26 million vehicles built. On top of that will be 60 hybrid vehicles. To this end, the Group will be investing over 60 billion Euros in electrification (35 billion) and in digitalisation (27 billion).

In parallel, Volkswagen is electrifying its own fleet of company cars: its managers must be the first to lead by example. In addition, investors have the opportunity to invest in the future of electromobility with Green Bonds. The funds help refinance projects related to the MEB platform and all-electric models such as the ID.3 and ID.4.

Green energy and recycling

A holistic approach is being taken in the transition to electromobility. Besides manufacturing cars, the Volkswagen Group produces battery cells, contributes to the development of charging infrastructure, and supplies green electricity through the subsidiary Elli.

Its batteries are guaranteed for 8 years or 160,000 km. Once they can no longer be charged to their full capacity, they can be used to store energy in charging stations before they are recycled.

Uses for spent electric batteries are being studied at the Salzgitter plant. Recycling processes are also being looked at, with the aim of creating a closed loop with a recycling rate of 90 percent.

Charging infrastructure and suppliers

Volkswagen provides 150,000 public charging stations throughout Europe with WeCharge. The stations can be accessed with a single charging card, which makes e-mobility much easier. In terms of procurement, the Volkswagen Group introduced a new rating system in 2019 that requires suppliers to establish clean production workflows and, particularly, to uphold human rights.

It monitors its supply chain for battery raw materials with RCS Global, an agency specialising in supply chain analysis. This focuses on assessing compliance with human rights, safe working conditions, and suppliers’ measures to protect the environment, starting from the mines.

A long journey

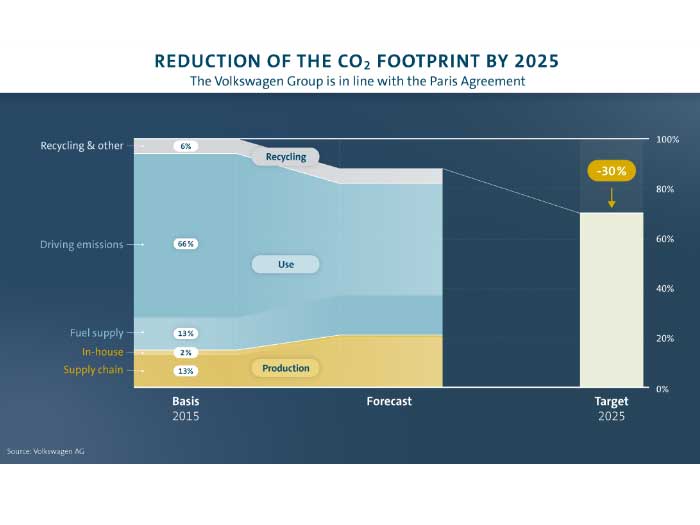

By 2030, the Volkswagen Group aims to reduce global greenhouse gas emissions from production and the use of its vehicles by 30 percent compared to 2018. The independent Science Based Targets initiative (SBTi) has certified that this objective meets the Paris Climate Agreement requirements.

Currently, 41 percent of the electricity consumed by the Group’s production processes is renewably sourced; the aim is to reach 100 percent renewable by 2030 (first, EU-wide by 2023 with the exception of ŠKO-ENERGO, then worldwide). 43 Group locations already use electricity from renewable sources only. In the meantime, its 125 manufacturing facilities worldwide are pursuing energy efficiency-boosting projects, with more than 1,650 new measures introduced in 2019 and 2020 alone.

The plants

The two power stations in the Wolfsburg Volkswagen plant will transition fully from coal to natural gas by the end of 2022. This will reduce the CO2 emissions of the two power stations by around 60 percent, or by 1.5 million tonnes each year.

The plants in Brussels (Audi), Zwickau and Dresden (Volkswagen), Vrchlabí (ŠKODA), and Crewe (Bentley) are the Volkswagen Group’s first carbon-neutral facilities. Volkswagen has also established a climate-neutral computer center in Norway with Green Mountain. Sourcing 100 percent of its electricity from hydroelectric power, it saves CO2 emissions of over 5,800 tonnes a year.

Transport

By 2021, all rail transportation of material and vehicle transportation in Germany will be converted to green electricity, avoiding more than 26,700 tonnes of CO2 emissions a year. For the Volkswagen plant in Palmela, Portugal, the Volkswagen Group reactivated a railway to transport finished vehicles to the port of Setúbal. The train will run up to four times daily and deliver around 500 vehicles to the port. That replaces 63 truck trips and cuts down on 400 tonnes of CO₂ emissions per year.

By using the two largest types of truck trailers on the market (31.7 and 25.25 meters long) for transportation at the SEAT plant in Martorell, Spain, Volkswagen is reducing CO2 emissions by 30 percent compared to conventional trucks.

As for maritime logistics, the Group already uses a freighter powered by liquefied natural gas with another slated for delivery soon. One full tank is enough for the entire Germany-Mexico-Germany round trip.

CO2 emissions

Through the CO2 fund, the Volkswagen Group supports all projects that reduce CO₂ emissions internally. The fund has an annual budget of 25 million euros. It has also incorporated a decarbonisation index (DKI) into the Group strategy as a transparent indicator on its roadmap to climate neutrality, with progress published regularly.

The corporate mission statement ‘goTOzero’ unites all environmental measures in one concept, embodying a sustainable way of doing business that minimises the Group’s impact on the planet. The four focus areas are climate change, resources, air quality, and environmental compliance.

In conclusion

The Volkswagen Group will achieve its goal of being carbon neutral by 2050 by taking an approach based on three steps: reducing energy consumption effectively and sustainably, switching to renewable sources, and compensating emissions that cannot currently be avoided. In conjunction with the electrification strategy, these three principles enable Volkswagen to effectively contribute to combating global warming.

In the words of CEO Herbert Diess: “We must not and will not miss any opportunity to further improve our resource efficiency and promote approaches to reuse and recycle materials.“

- ID.3 - combined power consumption (NEDC) in kWh/100 km: 15.4-14.5; CO₂ emissions in g/km: 0; efficiency class: A+.

- ID.4 - combined power consumption (NEDC) in kWh/100 km: 16.9-16.2; CO₂ emissions in g/km: 0; efficiency class: A+.

Source: Volkswagen AG