E-mobility vs traditional mobility: what carbon footprint data reveal

On the way to a climate-neutral future: taking the ID.31 as a benchmark, employees from Volkswagen’s Technical Development have examined how the carbon footprint of electric cars in Europe compares with that of internal combustion engines. The result is clear.

The debate on electric mobility grows ever deeper and more detailed. And few discussions are as passionate as those on vehicles’ carbon footprints; is an electric car really more climate-friendly than a car with a modern combustion engine? We’ve heard this question many times over the past few years. And at least one thing is certain: if an electric car is charged with green electricity, it does not produce any climate-damaging carbon dioxide emissions during its operation. But the carbon footprint of an electric car doesn’t just begin when the new owner presses the start button for the first time – the phases of the manufacturing process also need to be carefully considered.

By using green electricity (from renewable sources) and making its processes more efficient, the Volkswagen Group is systematically reducing CO2 emissions in production. Only the carbon dioxide that the Group and its suppliers are not yet able to avoid during production is subsequently offset through climate protection projects which are independently certified to the highest standards. This means that the Volkswagen ID.3 and ID.42 can be delivered to customers with a neutral carbon footprint.

Calculating the carbon footprint

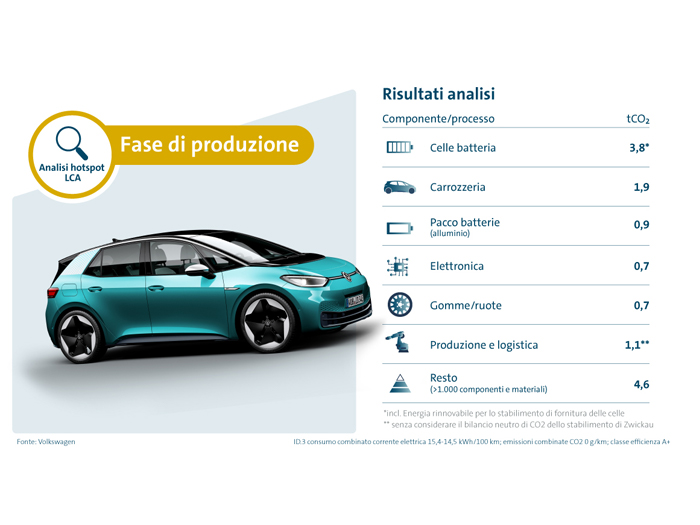

For the calculation of CO2 emissions to be accurate, the values related to each single component have to be measured correctly. Even the components themselves go through a step-by-step process to reduce their climate impact during production, starting with those elements whose production emits particularly high levels of CO2: the battery system, steel and aluminum. Six specialists in Volkswagen’s Technical Development unit have conducted in-depth analysis which leads to a clear conclusion: an electric car in Europe is already significantly more climate-friendly than a combustion engine over its entire life cycle. Let’s get more specific.

Evaluating the life cycle

The methodology for life cycle assessment (LCA) is based on the globally valid ISO 14040 standard. This takes all relevant processes into account with both the procedure and results requiring verification from an independent expert. Volkswagen has been preparing life cycle assessments ever since the Golf III in 1996, and has continued to optimise its methods and processes, as well as broadening its data basis.

Starting from the parts and materials list (with around 5,000 entries), all data is imported into a single piece of software. There, the resource input and CO2 emissions are calculated for the production of the vehicle. Ultimately, this comprises around 40,000 processes, which then map the entire production value chain.

Updating the database

The Volkswagen database, comprising several thousand data records and supplier data, is checked and updated annually. After all the information in the balance sheet has been verified by an independent expert, final certification is issued. The ID.3 balance sheet, for example, was certified by TÜV Nord.

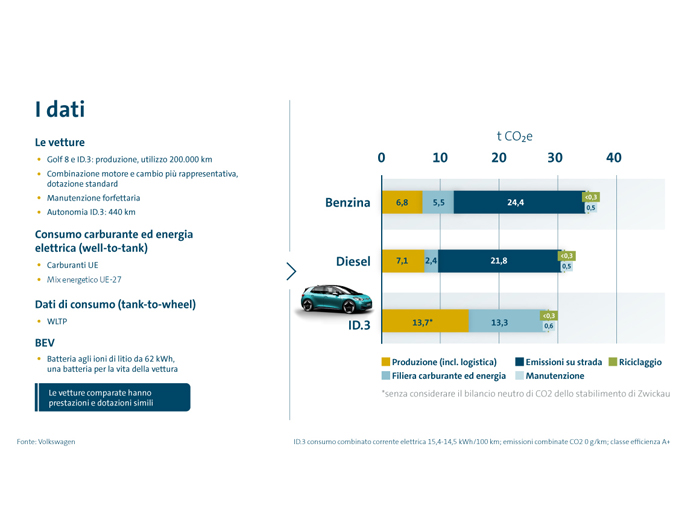

The same TÜV-certified balance sheets were used to compare an electric vehicle with an equivalent modern gasoline and diesel model. To ensure a fair comparison, the models were selected so that equipment and performance were as similar as possible.

Comparing emissions

As is clear from the graphic on the right (Fig. 1), the production of a fully electric vehicle (or BEV, Battery Electric Vehicle) currently generates higher emissions than for conventional vehicles. This includes all CO2 emissions of the cradle-to-gate value chain – that is, from the extraction of raw materials, through to the manufacture of semi-finished products and components. However, with an average European electricity mix, the BEV then achieves significant savings over a life cycle of 200,000 km, compared with diesel and gasoline-powered vehicles.

The production of the Li-ion battery has the greatest impact on the carbon footprint (Fig. 2). This is affected not only by the energy use in cell production, but also by the upstream processes in the supply chain: raw material extraction, cathode material production and the graphite for the anode all play a significant role.

The evolution of the battery

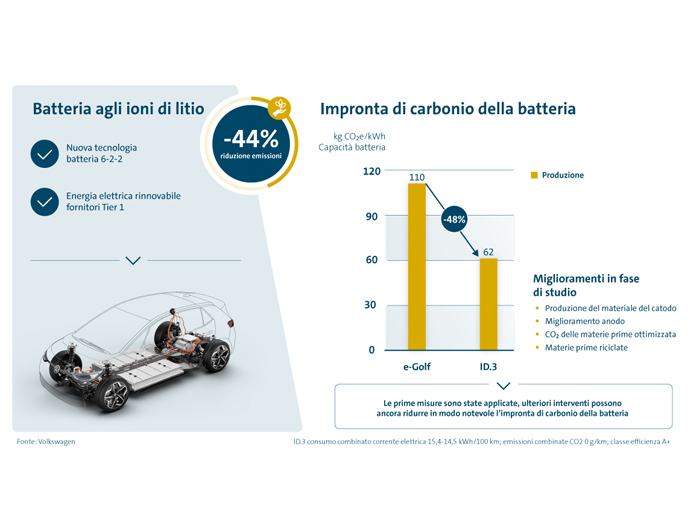

Compared with the battery used in the e-Golf3, the new generation of batteries in the ID.3, marks an enormous step forward: the new cathode material means capacity has increased without increasing costs. In addition, the Group has agreed with its battery cell supplier to only use green electricity to make them. These two measures have reduced the specific carbon footprint from 110 kg CO2e/kWh to 62 kg CO2e/kWh (Fig. 3). There is also great potential to reduce CO2 emissions in the production of cathode material and graphite, as well as for other key materials such as steel and aluminum.

Renewable energy sources

Even with today's European electricity mix, an electric vehicle is already more sustainable than a traditional vehicle, but with the further European Union’s planned energy turnaround with an increasing use of energy from renewable sources means carbon dioxide emissions will decrease even further. This will have a positive effect on electric cars’ overall CO2 balance. And this makes electricity the key energy source in the process of decarbonisation: a trend that is set to continue and intensify over the coming years, making electric mobility even more sustainable.

The efficiency of electricity

Of all the motors capable of powering cars, electric motors are the most efficient as they lose very little energy. Therefore, the use of locally generated, CO2-neutral clean electricity should be a priority for BEVs (and plug-in hybrid vehicles – PHEVs). Economic analyses of different energy sources and drives, including possible imports of eFuels or eH2 from sun and wind-rich regions, also show that battery-electric driving is the most cost-effective solution for the vast majority of drivers.

Being sustainable today

The use of green electricity in the usage phase has a clear positive impact – charging an electric car with energy from renewable sources means it is already possible to drive in an almost CO2-neutral manner today. E-mobility makes it possible to achieve a significant reduction in CO2 and marks an important contribution by the Volkswagen Group towards achieving the Paris Agreement climate targets.

1) ID.3 – power consumption in kWh/100 km (NEDC): 15.4-14.5 (combined); CO2 emissions in g/km: 0; efficiency class: A+

2) ID.4 – power consumption in kWh/100 km (NEDC): 16.9-16.2 (combined); CO2 emissions in g/km: 0; efficiency class: A+

3) e-Golf – power consumption in kWh/100 km (NEDC): 12.9-13.8 (combined); CO2 emissions in g/km: 0; efficiency class: A+

Source: Volkswagen AG