E-mobility: a battery for the lifetime…of a car

Batteries are the key component of every electric vehicle. Which is the best way to use them? What are the current and future scenarios? We take a look together.

With the e-revolution, a new concept of mobility is spreading - which inevitably leads to many questions about batteries, the heart of the zero-emission vehicles. Electric motors are quite simple from a technical point of view, and are also compactly sized – the most demanding challenge comes therefore from the batteries: their weight, positioning, and the energy they are able to store.

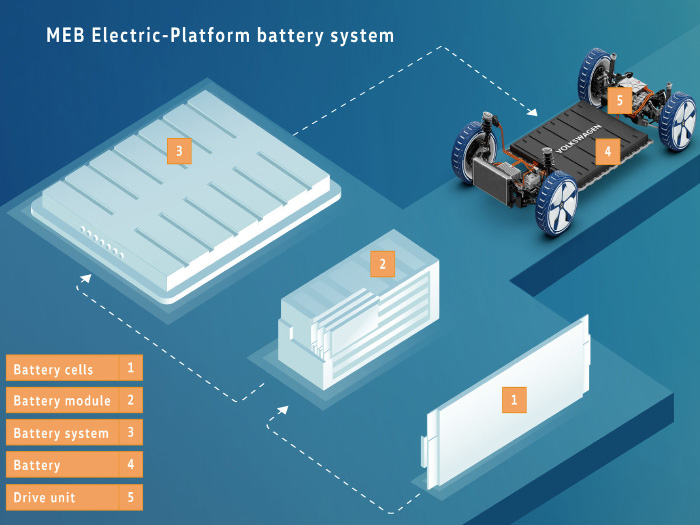

Volkswagen’s upcoming electric vehicles are designed around the battery, an approach which will allow ranges of up to 550 km to be achieved at affordable prices. While previously the modules used to be distributed in various places in the vehicle, now the battery is compactly located in the underbody, between the axles – this means that there is a central point for energy distribution, and this is one of the major advantages of the MEB platform.

Performance

The batteries for the new models, starting with the Volkswagen ID., are conceived to last as long as the cars (that’s the aim of the Group), with a minimum energy capacity of 70% guaranteed for 8 years or 160,000 kilometers. This duration is, however, also influenced by the driving behaviour, by the type of charging (fast charging is more “demanding”) and the percentage to which the batteries are charged – charging at 80% rather than at 100% increases their service life.

Moreover, for the daily use in most cases 80% is more than enough, since people tend to drive short distances – and for that it is not necessary to have the batteries fully charged all the time. Long journeys, on the other hand, impose different demands, and this is precisely why the Volkswagen Group is working with other manufacturers to create a network of fast charging stations along the European motorways.

Like a bar of chocolate

The battery systems developed by the Volkswagen Group are flat, shaped a little like a bar of chocolate. Every battery system is modular, in other words composed of a variable number of modules, which in turn consist of individual cells. The clear advantage of this type of structure is its flexibility: depending on the required range, the battery pack can be extended by incorporating more modules on the same basic architecture.

Currently, lithium represents the best available battery technology, and the energy density of lithium-ion batteries has doubled since 2014. The next big leap, expected between 2025 and 2030, will be to solid-state batteries, which will be lighter, cheaper and faster to recharge. The Group is already working on this with its partner QuantumScape .

Constant research

Battery research is always in progress, and in Salzgitter the Volkswagen Group has set up a Centre of Excellence focused on this technology, led by Frank Blome, who explains: “Our experts are working in all the fields: from developing battery cells to producing and recycling them. The site also has a specific high-voltage centre, where in-depth testing is carried out. The batteries have, indeed, to perform under extreme conditions for days and weeks at a time before they are approved approved for use in cars”.

Sustainable procurement

All of the suppliers of raw materials, even the most “critical” ones such as cobalt, undergo checks in terms of work ethics and employee rights, and must meet environmental and social standards, as well as any subcontracted suppliers. Currently, the Volkswagen Group is working with three partners as strategic suppliers of battery cells – LG Chem for Europe, SKI for Europe and the USA, CATL for China – and has recently joined the European Battery Union, a consortium which promotes research in the field.

Source: Volkswagen