Recycled plastic: a resource for car production

Owing to its properties, plastic is irreplaceable in the automotive industry. That’s why ŠKODA is continuously striving to increase the proportion of recycled plastic in the design of its vehicles.

ŠKODA’s commitment to sustainability also involves materials. In designing new cars its goal is to constantly increase the percentage of recycled materials used, and because these need to meet the same quality requirements as other materials, they are only introduced after thorough research. In the past, people would spend a lot of money on developing plastics with excellent and diverse properties.

“However, improving their recycling and re-use technologies was not the main priority,” says Jan Sláma, the Technical Development employee in charge of the development of materials and their durability at ŠKODA.

Limits and solutions

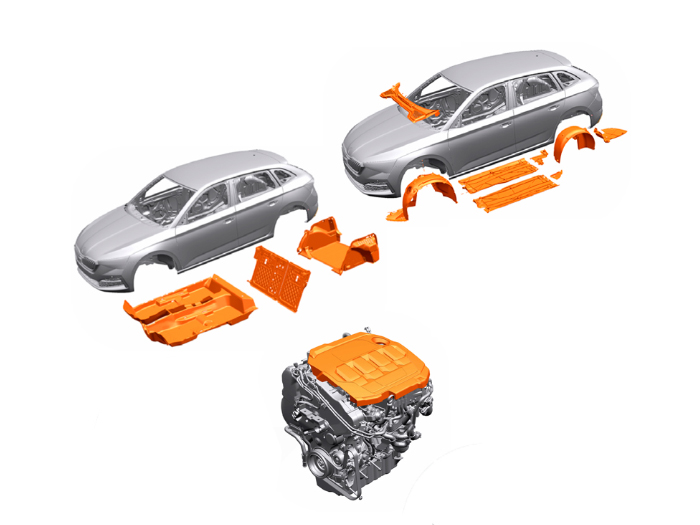

“We have to make sure that our choice of material does not limit the functionality of any part,” continues his colleague, Radka Kubínová. Therefore, recycled materials are mainly used in places where the part is subject to less stringent requirements. They are used to good effect on wheel arches, for example, or on chassis impact guards.

But they can also be used for more demanding applications, such as covering the scuttle drain, which is the drainage channel beneath the windscreen frame, or in future for panelling the luggage compartment.

Recycled materials

Recycled materials may result from unused parts made during parts production (post-industrial recycled materials). The recycling of old parts also involves materials that have been used once (post-consumer recycled materials); however, in this case, they are usually not 100-percent recycled.

“They must be supplemented with some new substances, and every production batch must be perfectly monitored. One good example includes the plastic covers under wipers whose production included 50 percent of the plastic from battery packs”, explains Lukáš Zuzánek, another member of the materials development team.

The role of plastic

As mentioned, plastic is irreplaceable in the automotive industry. It has substituted metal in many applications, contributed to lower car weights and reduced CO2 production and fuel consumption.

Incorporating recycled materials into the car interior is more complicated due to strict emissions and odour requirements. PET bottle recycling technologies have proved successful in the production of floor carpet and trunk flooring. Recycled textiles are used for floor damping.

New challenges

“In the case of polypropylene, the use of recycled materials is more difficult because the materials degrade during subsequent processing. Therefore, we must either have a source of raw materials of sufficient quality or apply a chemical recycling method,” says Kubínová. One of the new challenges is devising ways to increase the proportion of recycled plastic materials in the car interior.

The possibilities under development include fibres obtained from unused portions of coconut, flax, beet or coffee grounds that would serve as plastic fillers. All this is taking place with the aim of conserving natural resources and using waste material as much as possible.

Source: ŠKODA