Raw materials and blockchain: Volkswagen’s sustainability

Ensuring that all raw materials used in production are socially and environmentally sustainable: this is the Volkswagen Group’s challenge in the supply sector.

Achieving fully sustainable electric mobility means managing every single aspect of the vehicle life cycle, right from the extraction of the raw materials used in production. The Volkswagen Group is seeking different solutions, and will be participating alongside some start-ups and more established partners in a series of hackathons.

This is an important initiative for at least two reasons, as Marco Philippi, Head of Procurement Strategy, explains: “First of all, we work on concepts to bring the best possible transparency to our supply chains. This is because we only want to use raw materials that are obtained under humanitarian, sustainable conditions. Secondly, we want to support our employees’ engagement in social issues”. The hackathons the Group attended during 2018 were successful in both respects, and that’s the reason they are participating in this new round.

What are hackathons?

For some years now, and in many different contexts, companies have been organising these kinds of events known as hackathons: they were originally created as meetings between experts from the digital and IT worlds, with the main purpose of facilitating communication and innovation in the field of Information Technology: ad-hoc R&D teams are created, and attempts are made in many cases to create software prototypes. As mentioned, the current scenario is now much wider, and a growing number of companies – not necessarily linked to the IT sector – are using this formula to generate innovation within their business.

Efficient innovation

Last year, more than 100 Volkswagen Group employees participated in hackathons, and for one day put themselves at the complete disposal of start-ups in order to support them and help them develop their projects and new business models. It is a point of contact between two complementary worlds, between those who have innovative and unconventional ideas and those who have the experience and knowledge to put them into practice.

These events generated many good ideas to increase transparency in supply chains, such as the one developed with Minespider and based on blockchain technology to monitor the “journey” of raw materials from their point of origin to the automobile, results from which will be available at the end of 2019.

The supply chain

The main problem with supply chains is that they are long and convoluted. Some raw materials pass through nine processing phases before reaching the Volkswagen Group, and contracts are generally only with the direct suppliers, those at the first step. That makes it extraordinarily difficult to guarantee compliance with all environmental and social standards for each further step. In addition, supply chains often change: companies leave, other providers take their place; this makes it extremely difficult to have an up-to-date picture of the entire supply chain at all times.

The Group commits its suppliers to sustainability with well-defined standards which must also be met by the companies operating at the later levels, i.e. the sub-suppliers: if they don’t comply, they lose the contract. A specific rating tool has also recently been introduced, to allow the company to assess the conduct of its business partners in areas such as human rights, environmental protection and corruption.

Use of cobalt by the Volkswagen Group

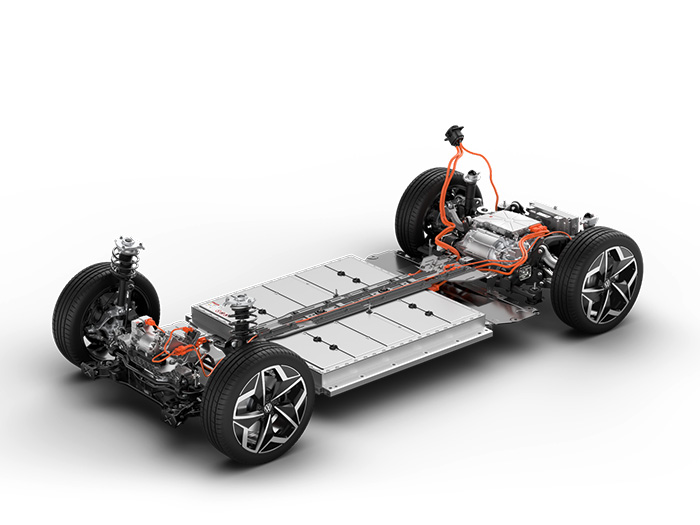

A concrete example of this is linked to procurement of cobalt, one of the elements required for the production of batteries for electric vehicles. There are two different methods of extraction: artisanal mining, where child labour really is a widespread problem, and industrial mining.

The company’s position is clear: it uses only raw materials which are “clean” from all points of view, so in this specific case it purchases cobalt exclusively from industrial suppliers – but is also working in the long term to significantly reduce the amount of cobalt used in the batteries.

The blockchain as a resource

In this framework, and in order to resolve the problems mentioned, the use of blockchain technology can have positive results in terms of management: it indeed allows tracking of the entire procurement chain, guaranteeing the authenticity of the process and its adherence to reality (through digital signing and encryption). Blockchain technology, moreover, initially used to create digital currencies such as Bitcoin, lends itself to very large applications, and one of these is management of each level of the supply chain – quickly, efficiently and safely, and supplying information on a global level for each individual step.

Source: Volkswagen AG