From the well to the wheel: the long road to zero emissions

A holistic approach covering the whole life–cycle of a car is the only way to reduce to zero the environmental impact of mobility.

Driving a car with low fuel consumption? Yes, but that’s not quite that simple. The awareness on a topic such as environmental protection can’t stop here, although it’s an excellent start - other elements have to be considered. Making mobility really sustainable is a very complex subject, of fundamental importance to the Volkswagen Group, which is pursuing the goal of becoming carbon neutral, meaning CO2–free in all its business activities. The key word for achieving this is decarbonization: a strategy of constant reduction in emissions, only feasible with a holistic approach.

Carbon footprint

In fact, it is essential to consider every aspect of a vehicle’s life-cycle: from the initial development up to the required raw materials, from logistics to production, from the first kilometre to the last on the road and, last but not least, from deregistration to recycling. “We bear in mind not only production and use, but also all the other phases, including those involving suppliers” explains Marko Gernuks, Head of Life Cycle Optimisation for the Group. Experts refer to the carbon footprint, environmental balance or Life Cycle Assessment (LCA). This is an ISO-standardised, systematic analysis of the environmental impact of a vehicle throughout the entire life cycle: an useful, reliable tool for assessing a car’s real environmental balance.

LCA - Car life-cycle

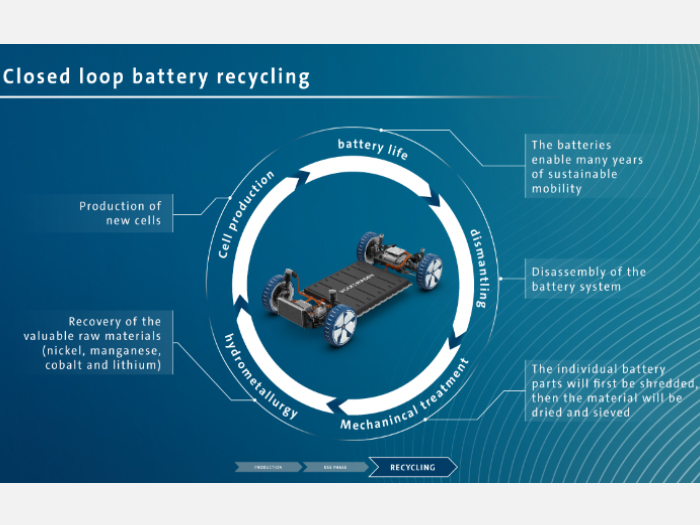

The life-cycle of a car is conventionally divided into three phases for the analysis, “from the well to the wheel”: production, which in turn includes raw material extraction, component and vehicle production; use, which covers fuel/electricity supply and vehicle emissions; and recycling, meaning the secondary usage of batteries or the processing and recuperation of valuable materials to enable a further use. The correct management of each of these aspects requires complex, in-depth analyses. “We take hundreds of factors into consideration for every single component; for example, the life cycle assessment for a tyre is prepared through 14 different processes” adds Gernuks.

Being carbon neutral

“It’s easy to say that the e-Golf has a bigger carbon footprint than a Golf diesel in terms of production, but after 125,000 km on the road the roles are reversed. This means we have to be very clear about the hot spots of each technology and where our priorities lie” concludes Marco Gernuks. The new Volkswagen ID., which will go into production at the end of 2019, will be the first completely carbon neutral Volkswagen. Emissions have been reduced from the beginning on, and climate protection projects have been activated in compensation for those which cannot be avoided.

Renewable energy

The battery system generates about 40% of the total emissions measured throughout the car’s life-cycle: the best, most immediate way of reducing them is to use renewable energy for producing battery. The use phase is as interesting as it is complex, since the driving behaviour is a subjective factor that, however, directly affects fuel consumption.

That’s why for the Volkswagen Group, electric mobility is currently the best technology for reducing emissions and achieving a really clean mobility – but here again, a car will be really emissions-free only if the electricity used to charge it is green. On this basis the Group has founded Elli, a subsidiary which supplies electrical power generated only from renewable sources.

Vision 2025

At the end of the car’s life is recycling, an extremely complex phase to which the Volkswagen Group is directly committed. After launching the research project LithoRec in 2009, for the purpose of attending to the recycling of lithium-ion batteries, a pilot recycling facility is currently being established for lithium-ion batteries at the Volkswagen site in Salzgitter: the goal is to optimize the process and to use salvaged raw materials to further reduce the carbon footprint connected with manufacturing of batteries.

Another benchmark for the Group is the “Decarbonization Index” or DCI, a key performance indicator for the “TOGETHER – Strategy 2025”, the vision of becoming one of the world’s leading providers of sustainable mobility, and being completely carbon neutral by 2050.

Source: Volkswagen AG