What robots used in automotive production look like and do

The definition of "robot" includes various types of machines. Which ones are most common in the automotive industry? What do they look like? What are their tasks?

What is a robot? Answering this is not easy: there is still not a single definition, although concepts such as robotics and artificial intelligence are more and more common. "The word robot is a bit like the word sweet: we all know what it is, but if everyone gave their own definition, the definitions wouldn’t be exactly the same", explains Jan Čejka, a robotics expert who works in the ŠKODA’s welding and electrical equipment planning team.

Robots like superheroes

Robots are like superheroes: they can work non-stop, don’t get tired and have superhuman abilities – they can easily handle loads as heavy as half a tonne without any problems. They are also far more precise than humans: they can perform linear movements in a straight line with incomparably greater precision than the most skilled surgeon. Last but not least, robots are great mathematicians: in a single instant they can recalculate all kinds of spatial coordinates, adjust the trajectory of the arm, and precisely grasp the required object.

Robotics, a comprehensive discipline

"Robotics is the king of engineering: it combines all the modern scientific and technical disciplines: mathematics, physics, programming, engineering, use of sensors, and design. If you like engines or are a programmer, you will find in robotics practically everything that can be studied in engineering schools. Research is also important, since all results can be applied in robotics: whether it's artificial intelligence, new materials or mathematics, everything is useful in the design of arms, gearboxes or the development of lubricants", Čejka continues.

Heavy and precision work

More than 4,000 robots work at ŠKODA: they are mainly used in welding, handling, and gluing; these processes account for about 85 percent of the robot activities, while the remaining 15 percent includes clinching, flanging, brushing, and laser soldering.

"Robotics is more complex in the places where a new part is being added to the assembly line and in the finishing area. It is precisely in these contexts that we are trying to integrate collaborative robots. We are also increasingly working with so-called vision systems, which are gradually automating the input: the robot can select the right part from the pallet and grab it itself", resumes Čejka.

The role of robots

Relying on robots makes more sense for routine and, especially, physically demanding tasks; the goal is not to replace human work but to make it easier. People are irreplaceable for much of the work: they make quick decisions, they have fine and precise motor skills, and above all, they can think. And anyway, someone always has to take care of the robots, keep them running, repair them, and program them.

Czech author Karel Čapek was the first to use the word "robot" in 1920, in his work R.U.R. (Rossumovi univerzální roboti, Rossum's Universal Robots). The main characters are "humanoid" robots that look and behave like people, except that they lack emotions; their role is to give people more time by working for them and in fact the word "robot" comes from the Czech word for feudal labour.

Stationary robots

Stationary robots are mainly used in industry; they operate only in a certain predefined space and it is by this that they are classified. The constraints are determined by the robot’s design, axis arrangement, length and number of arms.

Cartesian robots move in perpendicular axes and their workspace is a cube or block, while cylindrical robots cover an imaginary cylinder or sphere. The SCARA (Selective Compliant Articulated Robot Arm) is one of the latter: a cylindrical robot consisting mainly of rotating axes. It is small, fast, and precise, perfect for handling and assembling components, but also for fine alignment adjustments.

Articulated robots

The most common industrial robots are the angular or articulated ones. Six-axis industrial robots consist of two mechanical parts called the manipulator and wrist: they allow the robot to stretch and twist to the desired angle using the wrist. "Kuka robots are the most numerous in our welding shops - there are more than 2,500 of them. Then come the Japanese Fanuc robots, followed by the sixty robots from Swedish ABB. Suppliers must support our technologies and are chosen according to standards set in the Volkswagen Group. Each robot is programmed with our software and must be able to handle different tasks", Čejka further explains.

ŠKODA's six-axis robots are used extensively in resistance welding of the bodywork. There are thousands of welding spots, and each one is performed with a precision to the tenth of a millimeter. The robots are also equipped with a balancing function to adjust the position of the welding pliers relative to the metal sheet, compensating for any inaccuracies.

Service and wheeled robots

Service robots are non-industrial assistants that help people with non-productive tasks: a good example is robotic vacuum cleaners. And also, robots on wheels can move freely or on tracks. They are characterized by the number and arrangement of wheels, but also by their size and covering, and must be able to overcome various obstacles. They also have a navigation system and can perform all sorts of task, even collecting samples on Mars.

Their most common use in industry is as AGVs - Automated Guided Vehicles - and in fact they are the main robotic assistants in ŠKODA logistics. They help transport parts from the warehouse to the production line and can load a pallet directly onto the line thanks to wireless communication that makes the process safe.

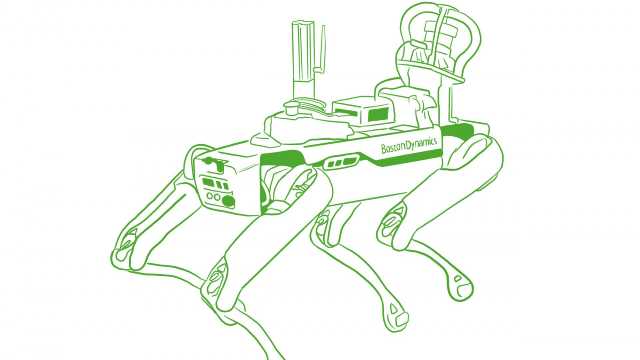

Walking robots

Walking robots have legs and feet to move around and often mimic the walking style of humans or animals so that they can better cope with difficult terrain. The main challenge here is to have a mathematical architecture of the control system that is robust and fast, to keep the robot balanced and synchronize the limbs perfectly.

In industry they are not widely used; ŠKODA uses them as part of the digital factory project: here several mobile platforms are being tested that scan production equipment to synchronize a digital model with reality.

Specialized robots

"The last category of robots is not perfectly defined, but we can call them specialized. These are the robots designed for specific skills such as swimming, flying or working in swarms. Then there are those as small as atoms – nano robots that might be able one day, for example, to help eliminate cancer cells in human bodies. Some robots can fight on battlefields, others help clean our homes", Čejka points out. Also worth mentioning are exoskeletons, functional structures that people wear to increase their strength, improve work ergonomics or even replace missing limbs.

"Our robots work in swarms in the welding shop: they communicate with each other and coordinate, literally giving each other the right of way, if they are in danger of collision. We have tested autonomous drones for logistics; in assembly they are common machines to improve ergonomics. Collaborative robots that share a workspace with a human without being separated by barriers can also fall into this category. Robots like these help us perform gluing or measure component dimensions", Čejka concludes.

Source: ŠKODA

VGI | Responsible OU: VP | Creation date: article date | Class 9.1