Robots and IoT: practical innovations for production

The collaboration between humans and machines is becoming ever more important to the Volkswagen Group. The basic goal is to continue increasing production line efficiency and ergonomics.

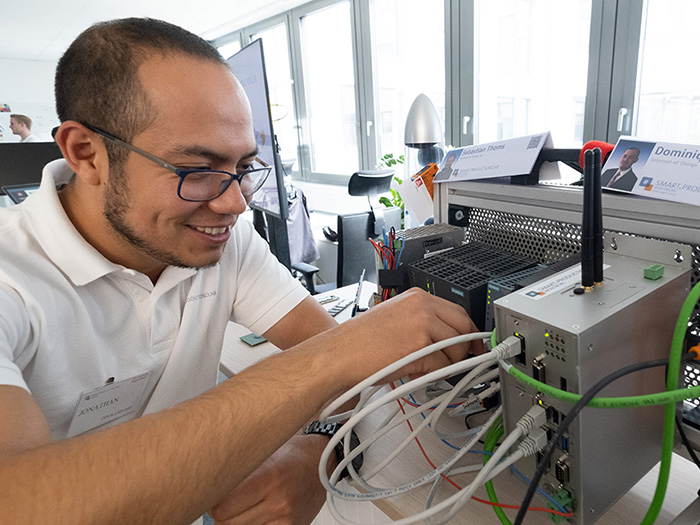

Which innovation actually helps Volkswagen Group‘s customers and employees? That is the question the specialists at the Smart Production Lab in Wolfsburg ask themselves every day.

Once a year this cutting-edge centre opens its doors for the Open Lab Day, to show journalists and professionals what they are researching. “We recruit the best IT experts from all over the world”, says Martin Hofmann, Head of Group IT at Volkswagen Group. “We are continuously doing research that is application-oriented, experimenting with technologies that aren’t available commercially anywhere.”

Future challenges

But, on a wider note, the real question for Volkswagen Group is how to best apply digitalisation to the future. Considering the global changes that have taken place in recent years, this is a crucial issue. Computing power has got faster and cheaper and many algorithms have become available for free in open source databases.

The question may be simple, but the answer is complex. The Volkswagen Group comes from classic mechanical engineering roots and with its 640,000 employees is more of a behemoth than a speed boat. “Innovations have to become established here,” Hofmann explains. In order to speed things up, the Group built IT Labs around the world, which have become specialised: in Munich the focus is on machine learning, the Smart Production Lab in Wolfsburg is about smart production, and Berlin hosts the Digital Lab, where many cloud-based applications are created. The Group also has IT Labs in Barcelona, Lisbon and in India.

Useful applications

It’s always important to combine IT expertise with engineering capability so that it has a practical application. That’s why IT experts today go directly to production, to the assembly line, and look at how they can genuinely help the colleagues there with their software solutions.

From this point of view, the Smart Production Lab has a big advantage as it is only a couple of hundred metres to the Wolfsburg production line. This allows it to experiment and decide quickly, concentrating on useful projects and not getting bogged down in projects which won’t end in success.

The Volkswagen Group pursues two premises in the process: developing its own software solutions to remain independent, and avoiding software being developed twice or constantly re-developed over and over again.

So what is the Smart Production Lab working on currently? Here are six examples of projects being researched:

- Automatic parts recognition: an AI system monitors parts and recognises differences and defects. That makes it possible for colleagues who aren’t specialised in IT to configure an independent order picking station in the future.

- Anonymisation in images: software recognises people in pictures. It protects their identity by pixelating their faces automatically.

- Smart cameras: software that examines which cameras are best for a specific purpose.

- Training robots: robot activities are configured freely. They learn their movements from humans by mimicking their hand movements. A subsequent image analysis checks the quality of the learned robot movements.

- Internet of Things: a sensor technology constantly measures various machine data such as current intensities and air flows allowing the software to predict when a machine is likely to malfunction, and plan maintenance.

- Sequence optimisation: algorithms developed in the IT Lab optimise production processes, thereby increasing the number of products on the production line. As production has to be highly flexible due to the wide range and number of models and variations, this plays an important role.

The goal of all these projects is clear: technology is never an end in itself. It should be used to make work even more efficient and ergonomically better for the employees. This also benefits the customers of the Group.

Source: Volkswagen AG