Electric cars: charging capacity vs. charging speed

Long-distance e-mobility is already a reality: Audi combines a high charging capacity with a sophisticated thermal management of the lithium-ion battery for fast charging speeds.

In order to assess the everyday usability of an electric car, customers should not just take its maximum charging capacity into account, but also – and above all – the charging speed.

Most charging processes of an electric car occur at home or at work, where the time factor generally does not play a substantial role. By contrast, every minute counts on a long-distance journey, because after a brief break the car should be ready for the next stage again.

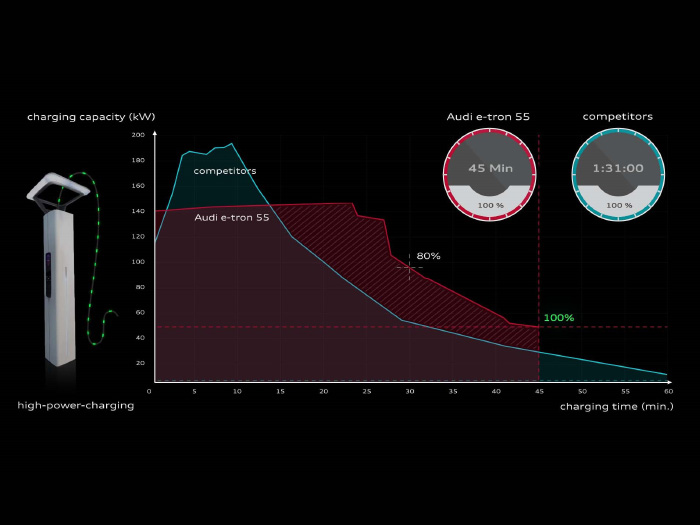

Many customers orient themselves toward the maximum charging capacity of their electric car – or how much energy it can store – to assess the charging characteristics of its battery. But there is another crucial factor when you refuel at a fast charging terminal: the speed of the process, so that charging duration is as short as possible. What counts most here is a high charging capacity that is available for as long a period as possible.

Charging power

The output at the charging terminal and high current consumption on the part of the battery may be necessary prerequisites, but a fast charging process depends above all on the charging speed (kWh / minute recharged) over the entire duration. If the car charges with maximum output over a relatively short period and needs to lower its power early, the charging speed is also simultaneously lowered and, as a result, stopping time is extended.

If you consider an ideal charging curve with maximum output available for a long period of time, the charging speed is the most important criterion when it comes to battery charging performance – ultimately, it guarantees a short duration at the charging terminal.

Charging times

For example, when the Audi e-tron 55* is connected to an HPC (High Power Charging) terminal with 150 kW, it can count on continuous output.

That means that under ideal conditions the battery charges between 5% and 70% state of charge at the threshold of the maximum output. Once this level is reached, the intelligent battery management reduces the current so as not to damage it.

Temperature management

The lithium-ion battery of the Audi e-tron 55 has a gross capacity of 95 kWh and has been designed for a long life cycle.

Its elaborate thermal management system forms the basis for well-balanced performance and durability. Liquid cooling ensures that the battery’s temperature remains in the optimum range of 25 to 35 degrees Celsius, even at high stress levels or low temperatures. For this reason, 22 litres of coolant circulate in the total of 40 meters of cooling lines in the four coolant circuits. During direct-current charging, cold coolant takes away the heat that occurs as a result of electrical internal resistance in the battery.

The cooling system

The core of the cooling system is made up of extruded profiles – visually comparable with a slatted frame – which have been affixed to the battery system from below.

A newly developed, thermally conductive adhesive joins the cooling unit to the battery housing. The gap filler forms the contact between the housing and the cell modules placed in it. This filler is a thermally conductive gel that evenly transfers the waste heat produced by the cells to the coolant via the battery housing. The spatial separation of elements and battery cells carrying cooling water also increases the overall system’s safety.

An additional positive side effect of this elaborate design is the high resilience in the event of a crash.

*Combined electric power consumption in kWh/100 km: 26.4–22.4 (WLTP); 23.1–21.0 (NEDC); combined CO2 emissions in g/km: 0

Source: AUDI AG