Volkswagen Industrial Cloud: an ecosystem for production efficiency

The Industrial Cloud will combine the data of machines, plants and systems from all the facilities of the Volkswagen Group.This will enable to analyse the processes and consequently to improve productivity.

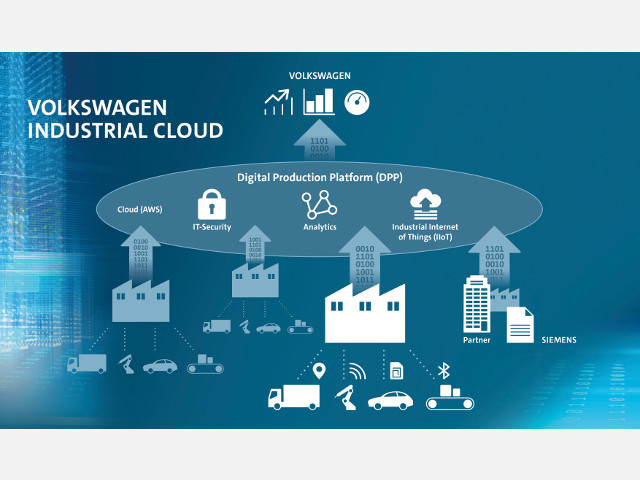

Increasing the efficiency of the facilities, to make them increasingly more productive. This is the goal of the agreement between the Volkswagen Group and Amazon Web Services, which are to jointly develop the Volkswagen Industrial Cloud. This platform will combine the data of all machines, plants and systems from all 122 facilities of the Volkswagen Group. Once it is fully operational, the cloud could integrate the global supply chain of the Volkswagen Group with more than 30,000 locations of over 1,500 suppliers and partner companies into the Volkswagen Industrial Cloud.

Siemens is also joining the project, ensuring that the machinery and equipment of the various manufacturers are connected to the cloud more effectively using MindSphere, an open IoT platform. This has many applications, including predictive maintenance of machines with optimized maintenance cycles calculated in advance, or processing of production data performed directly by the machinery and equipment.

The Industrial Cloud will be an open platform, meaning that in the future it may also be available for partners from industry, logistics and sales that can form networks and benefit from the open exchange of information.

Standardised and networked production

Through the development of the Industrial Cloud, the Volkswagen Group is laying the foundation for the complete digitalisation of its production and logistics. IT at the production level of machinery, equipment and systems – for example for production planning and inventory management – is to be standardised and networked across all 122 production plants of the Group, which currently have different management systems. The reference architecture will be the new Digital Production Platform (DPP), which all the Group’s plants and companies outside the Group will connect to.

Process optimisation

With the Industrial Cloud, new possibilities for further improving the efficiency and flexibility of production will open up. These include more efficient control of material flow, the early detection and elimination of supply bottlenecks, and the optimised operation of machinery in all plants. In addition, the cloud-based platform with its simplified data exchange, is an essential prerequisite for Volkswagen to provide new technologies and innovations rapidly across its various locations.These include smart robotics and data analysis functions to analyse and check shopfloor processes from plant to plant.

Global development

The Industrial Cloud will be developed both by the Volkswagen Group and Amazon Web Services. In the medium term, about 220 specialists are to work on the project. They are based at several Volkswagen IT competence centers, Experts in Dresden, Munich and Wolfsburg are to support further. Berlin will be also involved, with the opening of a joint Industrial Cloud Innovation Center. One hundred and forty projects have already been set in motion and the first applications will be available by the end of 2019.

Sources: Volkswagen; Volkswagen; Volkswagen AG