Sustainable design and digital technology for CUPRA's of the new era

CUPRA reinterprets the materials for its next-generation electric models. Flax, hemp and recycled plastics are key elements in this evolution, allowing increased sustainability.

CUPRA is preparing to enter a new era with the three brand-new electrified models unveiled a few months ago in Terramar, near Barcelona, that will come to market in the next years. CUPRA Terramar, CUPRA Tavascan and CUPRA UrbanRebel will not only write an electric future, but a more sustainable one, especially in terms of design.

CUPRA has created a new design concept by taking advantage of cutting-edge digital technologies: materials are transformed and acquire a new value, proving how sustainability and emotion can join and move forward together captivating new generations.

Color&Trim

Creating a new generation of electric models requires a comprehensive reinterpretation of interior and exterior design, with the aim of achieving maximum sustainability. This was the commitment of CUPRA's Color&Trim team: "We wanted to move away from the typical automotive material codes to focus on what new generations prefer; they value natural elements, respect the environment and promote sustainable growth. We believe that sustainability has given us the opportunity to reinterpret the authenticity of CUPRA", explains Francesca Sangalli, Head of Color&Trim Concept & Strategy at CUPRA.

Natural fibers

Sustainability is an integral part of CUPRA's philosophy, and with the upcoming electric models a further step will be taken. "We are experimenting with natural elements that are not conventionally used in the automotive industry", says Sangalli, who with his team is working with natural fibres such as flax or hemp to build parts that are normally made of carbon fiber. These plants also absorb a large amount of CO2, meaning that growing them benefits the environment. No compromise in quality: "The performance of the parts we are making with these fibers is comparable to Kevlar and carbon fibre", Sangalli adds.

Recycled plastic

Recycled plastics are also being used in unconventional ways. "We are creating parts for the car's interior with advanced recycled polymers without ever masking their natural look, reinterpreting plastic to make it beautiful to see and sustainable", Sangalli continues. Some interior parts have been transformed by introducing metal particles in them, which create a completely new finish.

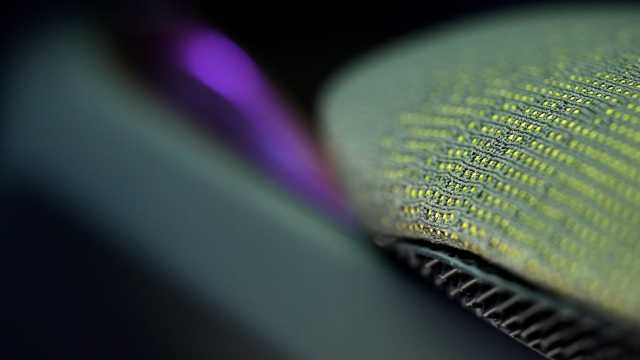

To reinterpret the design in this way, sustainability and creativity went hand in hand with state-of-the-art digital technologies. At the heart of this transformation are parametric design and 3D printing. "Digital technology has given us the opportunity to create incredible surfaces that come alive to the touch, generating a sense of movement. With the new techniques we have moved from 2D to 4D design, achieving structures that have become real showpieces", Sangalli recounts further.

Fabrics

Fabrics are also key players in this evolution: the Color&Trim department is continuing the path taken with eco-friendly materials by using vegan leather for CUPRA Born. Another innovative technology is 3D flat knitting, in which the fabrics are created entirely to measure to avoid waste.

"We are looking at a different architecture when it comes to design, to create a product from a different perspective using additive manufacturing. The result is an innovative, lightweight material that does not generate waste and allows for the creation of graphics within the material itself with a unique result. Sustainability is not just about recycling, but also reducing our carbon footprint", Sangallo concludes.

Source: SEAT S.A.

VGI | Responsible OU: VP | Creation date: article date | Class 9.1