Platforms, batteries and charging: the Volkswagen Group’s roadmap

A platform model for the vehicles of the future, battery costs halved, six factories with a total production capacity of 240 GWh, recycling of raw materials, 18,000 fast-charging points in Europe and an energy eco system: this is how the Volkswagen Group is accelerating its transformation.

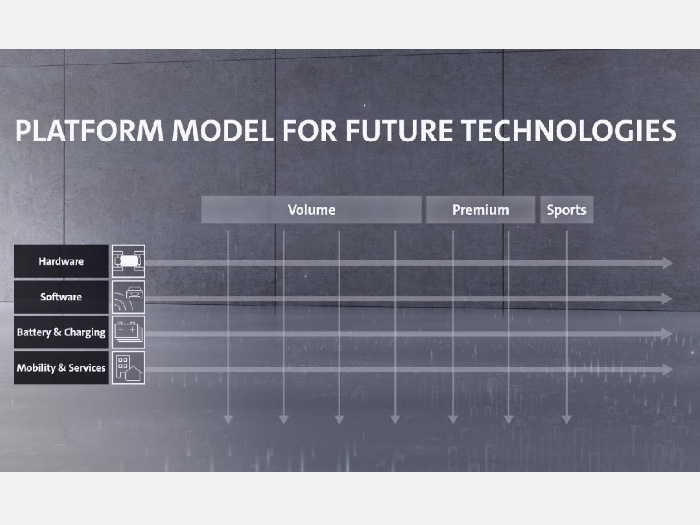

The Volkswagen Group is stepping up the pace of its transformation into the leading provider of individual mobility in the electric and fully connected age, thanks in part to enhancements to its platform model. In future, vehicles and services offered by all Volkswagen Group brands are to be based on largely standardised technical foundations. The future platform strategy has four elements: hardware, software, batteries and charging, and mobility services. This will reduce complexity and leverage economies of scale and synergies between brands.

“Electrification and digitalisation are changing vehicles faster and more radically than ever before. Economies of scale are absolutely critical for both issues. Our platform roadmap will put us in an even better position to tap the full potential of the Volkswagen Group as a whole. By pooling the strengths of our brands, we will thus be able to scale up our future technologies even faster and maximise the number of people benefiting from them,” said Herbert Diess, CEO of the Volkswagen Group.

MEB, PPE and SSP

The fully electric MEB platform is already one of the most powerful in the industry, and is scaling up globally with production in Europe, China and the USA. By 2022, the Volkswagen Group will offer 27 MEB-platform-based models; as early as next year, the Group will launch its first vehicles based on the Premium Platform Electric (PPE), with faster acceleration, higher ranges and shorter charging times.

And by the middle of the decade the Group wants to develop the Scalable Systems Platform (SSP) – the next generation of all-electric, fully digital and highly scalable vehicle platforms, suitable as a base for models from all brands and segments.

The VW.OS operating system

For on-board connectivity and software, the Volkswagen Group is aiming to achieve synergy effects across all its brands in the coming years. This is thanks to the VW.OS operating system supplied by Car.Software-Org.. Version 1.2 of the system will make its debut in the PPE, with version 2.0 subsequently being rolled out throughout the Group with the SSP. By then, the Volkswagen Group’s share of its car software developed in-house is set to rise from the current 10 percent to 60 percent. Car.Software-Org. is also developing the technical foundations for autonomous driving, data-based business models and new mobility services.

The next generation of batteries

The Volkswagen Group is also getting ready for the next generation of batteries, developing a new unified cell that will be installed in around 80 percent of all-electric vehicles across its different brands by 2030. This will reduce the cost of battery cells by up to 50 percent in the entry-level segment and by up to 30 percent in the volume segment. “We aim to reduce the complexity of the battery and drive down its cost to significantly below 100 Euros per kWh. At the same time we want to increase its range and performance. This will finally make e-mobility affordable and the dominant drive technology,” said Thomas Schmall, Volkswagen Group Board Member for Technology.

Further savings will be delivered by optimising the cell type and deploying innovative production methods, as well as consistent recycling. “We will use our economies of scale to the benefit of our customers when it comes to the battery too” Schmall explained.

The cell factories

To ensure that growing demand for battery cells can be met, the Volkswagen Group and its partners plan to build six cell factories with a total capacity of 240 GWh in Europe by the end of the decade. The first two factories – to be powered by renewable sources – will operate in Salzgitter and the Swedish city of Skellefteå, where cells for the premium segment will be built in collaboration with Northvolt. Production is set to commence in 2023 and will be expanded gradually up to an annual capacity of 40 GWh.

The Salzgitter factory will produce the unified cell for the high-volume segment from 2025 and develop innovations in processes, design and chemistry. Production capacity of up to 40 GWh per year is also planned for Salzgitter.

E-mobility and solid state cells

“E-mobility has become our core business. We are now systematically integrating additional stages in the value chain to secure a long-term pole position in the race for the best batteries and best customer experience in the age of zero emission mobility”, said Diess. Together with selected strategic partners, the Volkswagen Group aims to secure the long-term supply of cells. The new prismatic unified cell allows more energy to be stored at faster speeds. It will also cost less and offers an excellent foundation for the transition to the solid state cell – the next quantum leap in battery technology, expected for the middle of the decade.

The charging network

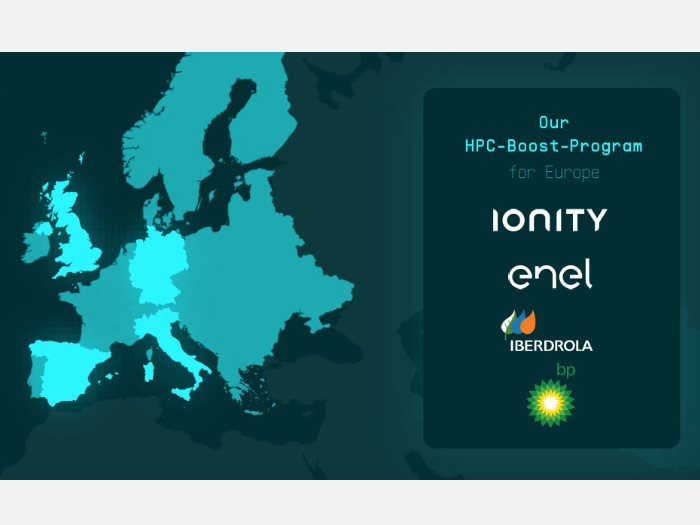

The Volkswagen Group’s battery offensive is being accompanied by a large-scale expansion of the fast-charging network in Europe, China and the USA. Along with its partners, and in addition to the IONITY joint venture, the Group intends to operate about 18,000 public fast-charging points in Europe by 2025. This represents a five-fold expansion of the fast-charging network compared to today and corresponds to about one third of the total demand predicted on the continent.

In collaboration with BP, Volkswagen wants to establish about 8,000 150-kW fast-charging points, with the majority in Germany and Great Britain. In cooperation with Iberdrola, the Group will cover the main traffic routes in Spain. In Italy, it will partner with Enel to establish the fast-charging network both along motorways and in urban areas. The Volkswagen Group will invest about 400 million Euros in the European programme by 2025, with further investments made by external partners. Electrify America is planning around 3,500 fast-charging points in North America by the end of the year. In China, a total of 17,000 fast-charging points are being targeted by 2025 through the CAMS joint venture.

The energy eco system and mobility services

Volkswagen intends to integrate the electric car into commercial, public and private energy systems in the future. This will allow green electricity to be stored in the vehicle and fed back into the network if needed. This means customers will be more independent of the public power grid, save money and reduce CO2 emissions. Models based on the MEB platform will support this technology from 2022. Volkswagen will also offer a complete package with all modules and digital services – from the bidirectional wall box to energy management, including for residential buildings and businesses.

Mobility services will also be integrated into a next-generation platform. These include the MOIA ride pooling service, the WeShare car sharing offering and flexible subscription services from Volkswagen Bank.

In 2020, the Volkswagen Group more than tripled its sales of all-electric vehicles. It aims to be the global market leader for electric mobility by 2025. To this end, it is planning to invest around 46 billion Euros in electrification over the next five years. By 2030, the share of all-electric vehicles in Europe is set to rise to up to 60 percent.

Source: Volkswagen AG