E-mobility: six advantages of the MEB platform

The MEB is the modular platform that will be the basis for a new generation of electric models. Here are the six main advantages it offers.

The electric revolution has begun: Volkswagen has opened preorders for the ID.3, which will hit the market in 2020. It is the first vehicle based on the MEB (acronym from the German Modulare E-Antriebs-Baukasten), the modular platform specifically conceived for electric vehicles, and will be swiftly followed by further models of other Group’s brands. The MEB represents a turning point for the entire automotive industry, and is a key element for the spread of e-mobility: by 2028 around 15 million of the Group’s vehicles will be built on the MEB.

Of the many advantages resulting from the use of this platform, here are the six most significant.

1. Economies of scale

In order to reduce the high costs for the development of electric cars, Volkswagen is offering its MEB technology platform to other car manufacturers. The concept underlying this choice is as simple as it is important: the more cars based on the MEB platform, the cheaper they will be. Using this platform will make the production process faster and more efficient, costs will be reduced, and as a consequence e-vehicles will become cheaper, and therefore more widely accessible.

2. Meeting climate goals

In order to meet the requirements of the Paris Climate Agreement, the German Ministry of Transport calculated that the sector would have to reduce CO2 emissions by 40 to 42 percent by 2030. This will only be possible if between seven and ten million cars are emissions-free by then. The number of new registrations of electric cars would have to increase – dramatically. The modular electric drive matrix could be a decisive factor in moving closer to this goal and thus to Volkswagen's vision of a mass-produced electric car.

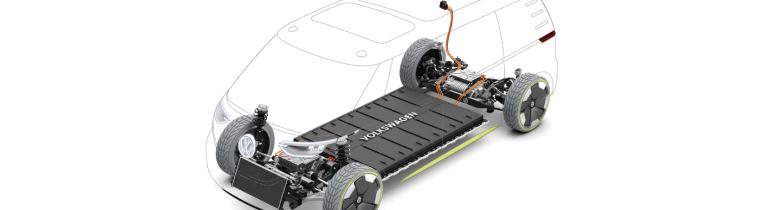

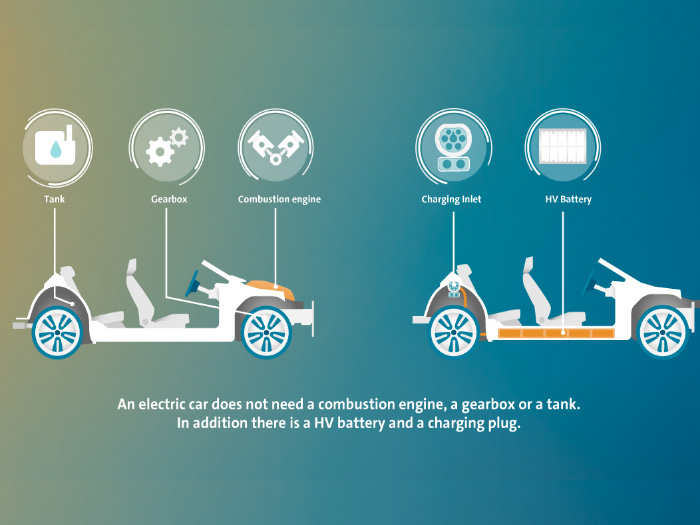

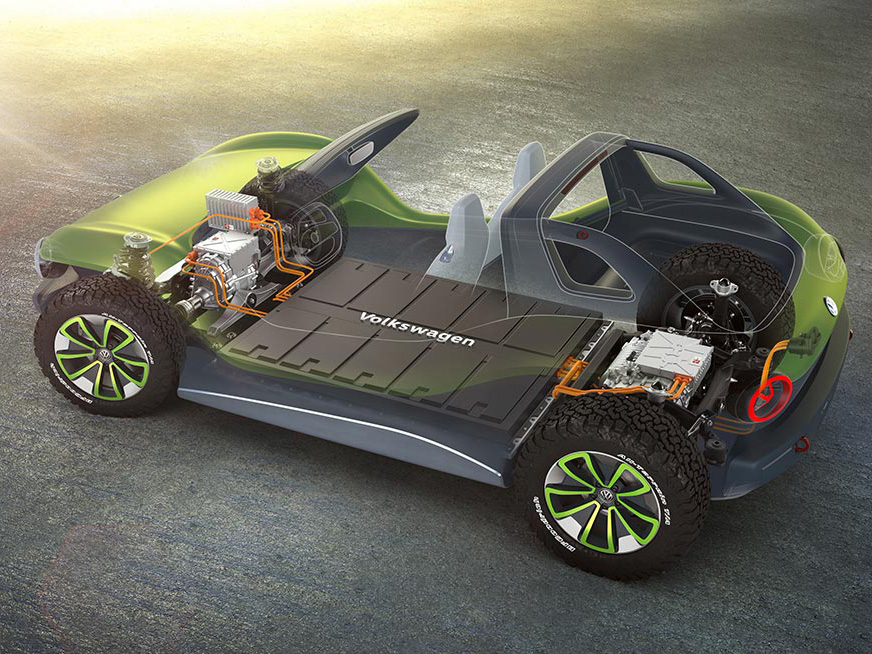

3. More space, more comfort

The MEB platform has been specifically designed for electric mobility: the large wheelbase translates into much more space available on board, also helped by the lack of thecardan tunnel and by the compact size of the electric motor, which is integrated in the rear axle with the power electronics and transmission. The auxiliary units are located in the front part of the vehicle, while the battery is flat and positioned in the vehicle floor. With this configuration, space on board is increased dramatically: the ID.3 has the dimensions of a Golf, but as much interior space as a Passat.

4. Flexibility and customisation

Audi, SEAT, ŠKODA – the MEB platform meets the needs of the Group’s various brands, which can use it without giving up on their own identities, with different chassis and bodywork characterising the vehicles. As said, the first MEB-based model is the Volkswagen ID.3, which will be launched on the market from 2020 – production begins in Zwickau at the end of 2019 – at a base price of less than 30,000 Euros, offering 170 HP and range of up to 550 km (WLTP).

5. Modularity and competitiveness

The MEB is also a suitable technological solution for small production series of vehicles, allowing such models to remain competitive. A concrete example of this is the e.GO Life, a city car developed by the manufacturer e.GO Mobile, the first external partner to use the Volkswagen Group’s platform.

6. Made-to-measure batteries

Short, medium or long distances? It makes no difference: the MEB can be tailored to the individual use of the car. This is possible thanks to the scalable structure of its battery system, which can be configured with three different capacities, allowing customers to select the option which best suits their driving habits.

Source: Volkswagen AG