Why is the electric car the future of mobility? Here are five reasons

What are the characteristics of electric vehicles and those powered by hydrogen or synthetic fuels? What are the best in terms of emissions and environmental sustainability? Here are the answers.

Are electric cars really the future of mobility? Wouldn’t hydrogen or synthetic fuels be a better option? For a large number of scientists, this question has already been answered. “Many studies have shown that electric drive is by far the most efficient method for powering cars,” says Prof. Maximilian Fichtner, internationally renowned battery expert at Karlsruhe Institute of Technology (KIT). We have summed up everything you need to know about the debate in five points.

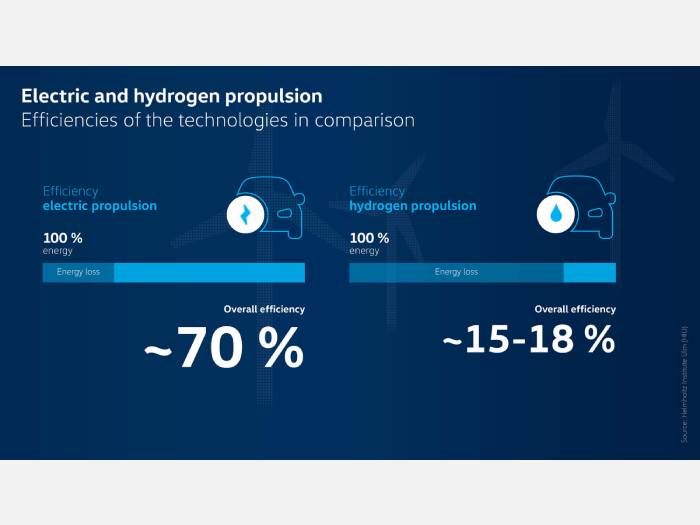

1. Electric cars are the most efficient

Electric cars make the most out of the energy used: 70% of the energy generated reaches the wheels. For hydrogen this is 15-18%, today’s combustion engines 20-24%, and for synthetic fuels 5-8%.

Electric drive benefits from working according to a simple principle: the energy is stored in the battery and sent to the motor as required. Hydrogen, on the other hand, passes through a laborious manufacturing, transportation and conversion process before it reaches the fuel cell in the car. This results in high loss of energy. The losses are even greater with synthetic fuels, also known as e-fuels: it takes 162 kilowatt hours (kWh) of electricity to produce the six litres of e-Diesel required to travel 100 kilometres (with fuel economy of 6 l/100 km). “With that amount of energy, you can drive a battery-powered car 1,000 kilometres,” explains Fichtner.

2. Electric cars have ever-greater range

Electric cars already have ranges suitable for everyday use. The Volkswagen ID.3, for example, can travel up to 549 kilometres with a 77 kWh battery, up to 426 kilometres with a 58 kWh battery, and up to 352 kilometres with a 45 kWh battery (WLTP). Technological progress – optimisation of cells, batteries and energy management – will significantly increase these distances, making a range of even 1,000 km plausible.

In this field, the Volkswagen Group is also working with partner QuantumScape on the development of solid-state cells, with the goal of greater ranges and shorter charging times.

3. Electric cars have the best climate footprint

Electric vehicles have the best climate footprint, as a large number of scientific studies show. The sustainability of electric cars has also increased significantly in recent years, thanks to progress in battery production, the longer lifetimes of batteries and the growth of renewable energy production in Europe. “Compared with combustion engines, it still takes more energy to manufacture electric cars. But that is offset after a few tens of thousands of kilometres, providing clean electricity is used,” confirms PSI research scientist Christian Bauer.

4. Electric cars protect their surroundings

Electric cars avoid or reduce local emissions, with significant advantages compared to other technologies: this is true when it comes to emissions of particulate and NOx, as well as noise. For example, the sophisticated acoustics of the Volkswagen ID.4 make for a very quiet journey, thanks to details such as the shape of the exterior mirror casings and elaborate insulation measures in the chassis; these reduce the airborne sound and structure-borne sound that the engine, chassis and tyres emit, contributing to the impression of almost silent power delivery.

5. Electric cars facilitate the energy revolution

Unlike with hydrogen or synthetic fuels, a total transition to electric cars would significantly reduce the energy needs of the transport sector, due precisely to the high level of energy efficiency of electric drive (see point 1). Using the figures from 2018, Fichtner estimates energy savings of more than 75% in the transport industry if all 48 million of Germany’s passenger cars were converted to all-electric. This is because, as explained above, electric cars require a lower volume of energy to be generated. A full transition to hydrogen cars would, on the other hand, increase energy requirements by around a third.

Raw materials and sustainability

The spread of electric mobility will also require expansion of charging infrastructure and the procurement of battery raw materials such as lithium and cobalt using sustainable supply chains. Volkswagen is in the front line of both these areas. At the beginning of 2021 it introduced an innovative new raw materials management system, setting universal sustainability standards for mining and processing 16 particularly risky materials. These include those required for batteries: lithium, cobalt, nickel and graphite.

The objective is to increase transparency along the supply chains, for example, through certified audits and the use of blockchain technology. All suppliers have also been subject to a sustainability rating since 2019, in which environmental and social standards are on equal footing with criteria such as costs and quality.

Cobalt and lithium

In Congo, Volkswagen and other partners are running the Cobalt for Development project to improve the health and safety conditions, as well as living conditions, of people in the communities around the mines. Volkswagen is also a member of the Responsible Lithium Partnership, which advocates responsible management of natural resources, including lithium, in Salar de Atacama, Chile.

Charging stations

As regards the infrastructure, by 2025 the Volkswagen Group is aiming to operate around 18,000 public rapid-charging stations in Europe in collaboration with partners. This will increase the European rapid-charging network by a factor of five and provide around a third of the predicted total requirement on the continent for 2025.

The Group is also working on expanding the rapid-charging network in North America and China. With Electrify America, around 10,000 HPC stations will be installed in the USA and Canada by the end of 2025, while a total of 17,000 rapid-charging stations will be set up in China via the CAMS joint venture in the same timeframe. The Group already sells home chargers via its subsidiary Elli, supplied entirely with electricity from renewable energy sources.

CONSUMPTION DATA OF THE MENTIONED MODELS

Volkswagen D.3 - combined power consumption in kWh/100 km (NEDC): 15.6-13.1, CO2 emissions in g/km: 0; efficiency class: A+03.

Volkswagen ID.3 Pro S (77 kWh), 150 kW/204 PS - combined power consumption in kWh/100 km (NEDC): 14.1–13.5; combined CO2 emissions in g/km: 0; efficiency class: A+04.

Volkswagen ID.3 Pro (58 kWh), 107 kW/146 PS, combined power consumption in kWh/100 km (NEDC): 14.1–13.4; combined CO2 emissions in g/km: 0; efficiency class: A+05.

Volkswagen ID.3 Pure Performance (45 kWh), 110 kW/150 PS - combined power consumption in kWh/100 km (NEDC): 13.8–13.1CO2 emissions (combined) in g/km: 0; efficiency class: A+06.

Volkswagen ID.3 1ST - combined power consumption in kWh/100 km (NEDC): 14.5, CO2 emissions in g/km: 0; efficiency class: A+

Volkswagen ID.4 - power consumption in kWh/100 km (NEDC): combined 17.5-15.5; CO2 emissions in g/km: 0; efficiency class: A+

Volkswagen ID.4 1ST, 150 kW – combined power consumption (NEDC) in kWh/100 km: 16.2; CO₂ emissions in g/km: combined 0; efficiency class: A+09.

VGI | Responsible OU: VP | Creation date: article date | Class 9.1