The gearbox of an electric car: how is it made?

The way electric motors work means traditional transmissions are not required. That’s why the new Volkswagen ID.3 gearbox has a single gear, is extremely compact and quiet.

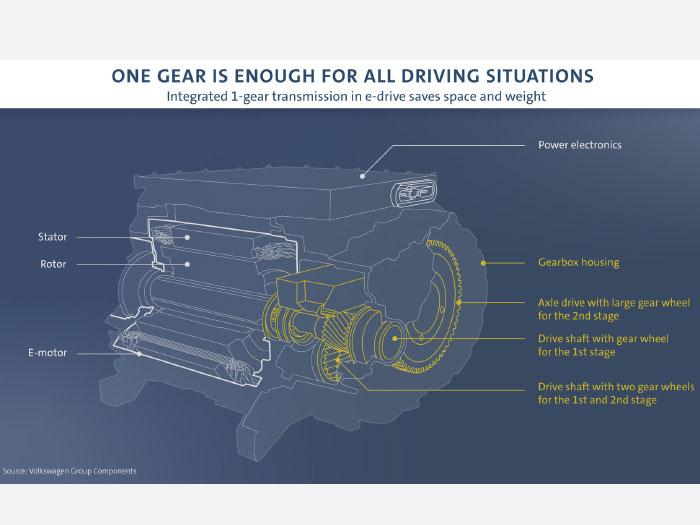

The ID.31 ushers in a new era of e-mobility for Volkswagen. The typical features of its electric drive system - the small but very powerful APP310 - make the use of traditional transmission systems unnecessary. As the maximum torque is available immediately, a single-speed gearbox is sufficient under any driving conditions. In addition, it uses a small number of cogs, meaning that it is extremely compact.

The gearbox is a key part of the electric drive system for vehicles that use the modular electric drive matrix (MEB) and is manufactured by Volkswagen Group Components at the Kassel plant.

What is the gearbox for?

The traction - the force that allows movement - and speed of a motor vehicle depend on the rotational speed of its drive system, which is in turn linked to the power that the system can generate. As the speed of the drive system increases, the force transmitted to the wheels (the torque) can vary.

In vehicles using combustion engines the torque increases in line with the engine speed. With an electric drive system, however, the maximum torque is available immediately and remains constant over a wide range of speeds. Conventional cars require multi-speed gearboxes to achieve the right torque along the speed curve. When it comes to electric cars, however, they are simply not necessary.

Torque and power

The Volkswagen ID.3 comes with a two-stage one-speed gearbox. When reversing the car, the direction of the electric drive system is simply reversed through a command from the on-board electronic control. In order to achieve the maximum power of 150 kW, the electric drive unit must rotate at high speeds, and a 10x transmission ratio is used to generate a high level of torque.

To save space, the gearbox has a two-stage design with two smaller cogs instead of a single large one. As a result, the ID.3’s electric drive motor provides the maximum torque of 310 Nm constantly across a wide range of speeds. The maximum speed of 160 km/h is reached at 16,000 rpm.

The sound of silence

Because electric drive systems are very quiet, soundproofing in e-vehicles is important - even the tiniest noises can immediately become apparent. That means that gearbox parts must be manufactured with great precision to ensure they are not the source of irritating noises. Therefore, at the end of the production line relevant noise values are checked, as well as the power characteristics of the electric drive system.

All drive systems for European and North American e-vehicles based on the MEB are manufactured at the component plant in Kassel. Other parts are produced at the component plants in Salzgitter, Poznań and Hanover.

1 The vehicle is not yet on sale

Source: Volkswagen AG