Smart solutions for efficient and sustainable logistics

Digital technologies are redefining international logistics. Here are some of Audi’s innovative solutions.

For Audi, “smart logistics” isn’t a vision of the future but a part of reality today. Shelves that label themselves, cooperation in virtual spaces, and high-performance computers that make autonomous decisions - these solutions aim to optimise processes in order to improve quality and reduce environmental impact.

Digital labelling: cutting-edge display technology

The company tested digital shelf labelling at the Audi plant in Győr, Hungary, for the first time last year. This new technology employs what are known as e-ink displays, which are also used in e-book readers. When information about a product or the arrangement of parts on the shelf change, the logistics specialists no longer need to update the labelling by hand. Information can be displayed at very short notice - for example if a part is out of stock and needs to be replaced with a different part.

There are other advantages of digital displays too, including immunity from the likes of mites, mould and bacteria, a reduction in waste paper and very low consumption of electric energy, even in continuous operation. The German/Hungarian project team is currently working on enhancing the technology, with one of its goals to implement fully automatic updates. Series production in the near future is conceivable, including at other Audi sites.

Digital shelf labelling marks another step for Audi toward smart logistics, with the aim of improving efficiency levels and reducing paper consumption and waste. Audi employees already work with tablets and hand-held scanners when gathering parts.

Smart logistics: driverless systems and flexible procedures

Digital helpers like these are just one example of the use of smart technology in the automotive manufacturer’s Logistics division. “We are making targeted use of the advantages of digitalisation at our production sites worldwide” says Dieter Braun, Head of Supply Chain.

Driverless transport systems have been in use at the Audi plants for many years. They transport parts to the workstations automatically using laser scanners to orient themselves in the production hall and find the optimum route, even without a fixed assembly line sequence.

This highly flexible procedure is made possible by algorithms and machine learning, controlled by a smart IT system in the control station. This allows the IT system to keep track of all systems, all driverless transport vehicles, and the product.

Effibot: a valuable resource

At the Pre-Series Logistics department in Ingolstadt, Audi is currently the first automotive manufacturer to trial a new driverless transport system, which follows employees around and supports them in their work. The “Effibot” uses laser sensors to detect the employee’s legs and follows them automatically at low speed.

All it takes is a touch of a button – the system requires neither complicated adjustments nor any special infrastructure. Its autonomous driving function also allows the “Effibot” to head towards previously defined destinations independently.

The employees welcome the pilot project: they have an assistant that helps them with their work in complete safety and they no longer need to push order picking trolleys by hand. This leads to a reduction in stress and significantly increases productivity and work quality levels.

Virtual reality and packaging logistics

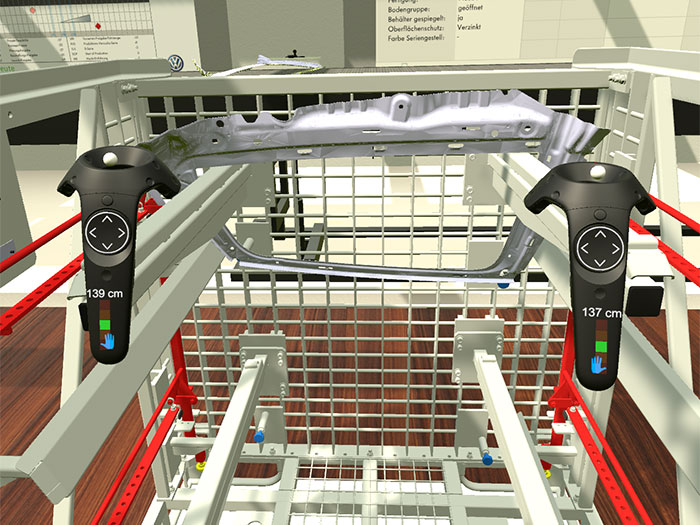

Another smart solution brings Audi employees worldwide together: virtual reality (VR) means they can work together group-wide and across locations in virtual spaces. In Packaging Logistics, for example, employees have been training with VR for several years. The training is designed like a video game and can be adapted to suit other activities as well – no programming skills are required. The company is also counting on VR technology in the production of the Audi e-tron GT, which will begin to roll off the line at the Böllinger Höfe factory this year.

As part of a pilot project, logistics planners in Neckarsulm are developing and testing special containers in a virtual space without any physical prototypes. These containers are used for particularly sensitive parts such as electrics, headlights, or the windshield. They are custom-made for this task and require a significant amount of planning - developing the special containers with VR is less expensive and is also better for the environment.

Mathematical models to manage storage

The Smart Decisions team at Audi addresses even more complex planning processes. The experts “translate” a wide range of issues into mathematical models, and a high-performance computer uses these as a basis to find solutions for logistics-related problems, for example the external storage forecasts.

As part of the delivery process, certain models may have to be put into interim storage for a short time. But which of the storage areas is suitable? Numerous factors influence the answer to this question. They include the distance between the respective parking lot, the plant and the delivery destination, the cost for transportation and the capacity of the parking lots. The mathematical model created by the Smart Decisions team allows these vehicles to be distributed optimally across the storage areas.

Source: AUDI AG