More efficient logistics and diagnostics with AI apps

ŠKODA has developed OPTIKON and Sound Analyser, two apps that use artificial intelligence to make work faster and more accurate as well as more efficient and sustainable. And a smartphone is all that’s needed to use them.

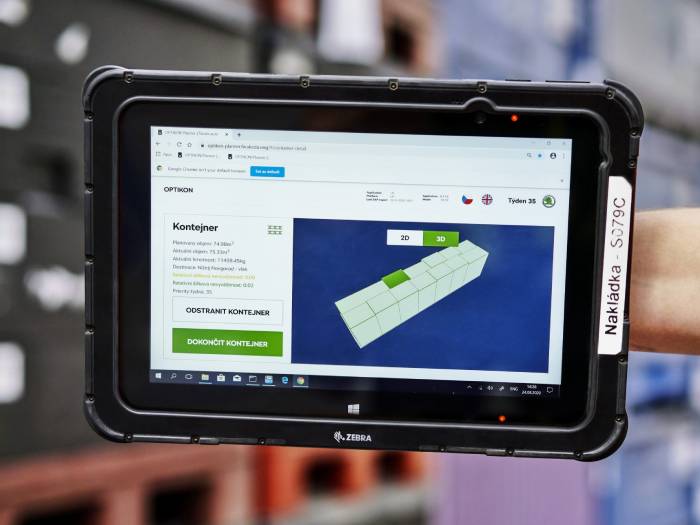

Loading a 12-metre (40 feet) container without leaving any gaps is like playing Tetris on the hardest setting – something ŠKODA’s logistics experts at the Mladá Boleslav plant know only too well. However, since November 2019 they have been supported by OPTIKON, an app that uses artificial intelligence to calculate how and in what quantity different pallet types should be loaded to maximise the container’s loading capacity.

This allowed ŠKODA to save 151 container shipments and 80 tonnes of CO2 emissions in the first six months of 2020 alone.

The OPTIKON app

“This app is a major step on our way to digitalising logistics and our work processes. The OPTIKON project makes the work of the employees in the parts warehouse easier whilst also lowering our transport costs and CO2 emissions,” explains David Strnad, Head of Brand Logistics at ŠKODA AUTO.

There are endless ways to fit pallets – of which there are 400 different types, all in a variety of sizes – into a container, making loading a very challenging task for logisticians. The OPTIKON app, which was jointly developed by ŠKODA AUTO Logistics and ŠKODA IT, uses artificial intelligence to make maximum use of each container’s capacity.

Industry 4.0

The name OPTIKON is an amalgamation of OPTImisation and the Czech term ‘KONtejner’. “The app illustrates how we use artificial intelligence technologies and Industry 4.0 at ŠKODA to make everything we do even more efficient,” adds Klaus Blüm, Head of ŠKODA IT.

The program also balances the weight distribution within the container and checks that the freight will be shipped in good time. OPTIKON is used in particular for loading containers with body components and production materials to be shipped to the Nizhny Novgorod plant in Russia.

Combinatorial analysis

OPTIKON’s artificial intelligence program uses mathematical combinatorial analysis methods to find various solutions to what is known as the ‘knapsack problem’. This addresses the question of how certain objects can be optimally fitted into a limited space. However, while the classic ‘knapsack problem’ only takes into account the weight and value of the items to be packed, OPTIKON also considers the floor space, the volume of the freight item and when the goods have to be shipped.

The Sound Analyser app

Sound Analyser is the name of another artificial intelligence-based app, developed by the ŠKODA AUTO After Sales department and ŠKODA AUTO DigiLab.

It is designed to quickly and accurately help identify the need for any servicing. The program records noises made by the respective vehicle whilst it is running and compares them with sound patterns stored in a database. In the event of any discrepancies, an algorithm determines what they are and how they can be resolved. As a result, Sound Analyser helps make vehicle maintenance faster and more efficient.

Digitalisation

“This app is a prime example of the new opportunities digitalisation can create. We will continue to use artificial intelligence to offer our customers an even more personalised service and further improve their experience,” explains Stanislav Pekař, Head of After Sales at ŠKODA AUTO. This is echoed by Blüm: “At ŠKODA, we are consistently looking to comprehensively digitalise processes, products and services. We want to be able to recognise the potential of innovations early on, develop them quickly and use them intelligently. That’s why we are working with the specialist departments to jointly implement new digitalisation projects.”

Diagnostics

The Sound Analyser app uses artificial intelligence to reliably, clearly, and quickly assess the current condition of parts susceptible to wear and notify technicians of any servicing required. The program considers various vehicle-specific parameters, making it even easier for technicians to perform accurate diagnostics on a vehicle as – just like with OPTIKON – they will only need a standard smartphone or tablet to use the app.

Although the program is complex, its operation is intuitive: the sounds made whilst the vehicle is running are recorded via a smartphone. An algorithm then compares them with those stored in the database and provides the result. Currently the software can recognise ten patterns, with an accuracy of over 90 per cent, for components such as the steering system, air conditioning, and the gearbox.

Neural network algorithms

Neural network algorithms provide the technical basis for Sound Analyser: the app first converts the audio file into a spectrogram that visually depicts the acoustic signals. Using artificial intelligence, this representation is then compared with the stored recordings to identify deviations and the need for upcoming maintenance or repairs. Since June 2019, the app has been in a pilot project trial involving 245 dealers in 14 countries, including Italy. The data they have provided have directly contributed to the program’s development.

Predictive maintenance

In the future, sound recognition technologies will open up a wealth of new possibilities for sensor-based, predictive maintenance. In addition, the vehicle’s online connection can be used to arrange an appointment directly with the garage if necessary. Artificial intelligence-based technologies can interact with their environment, perceive and weigh up facts, or solve specific problems. As one of the cornerstones of ŠKODA’s 2025 Strategy, AI plays a key role in advancing the levels of digitalisation even further, including for services and personalisation.

Source: ŠKODA