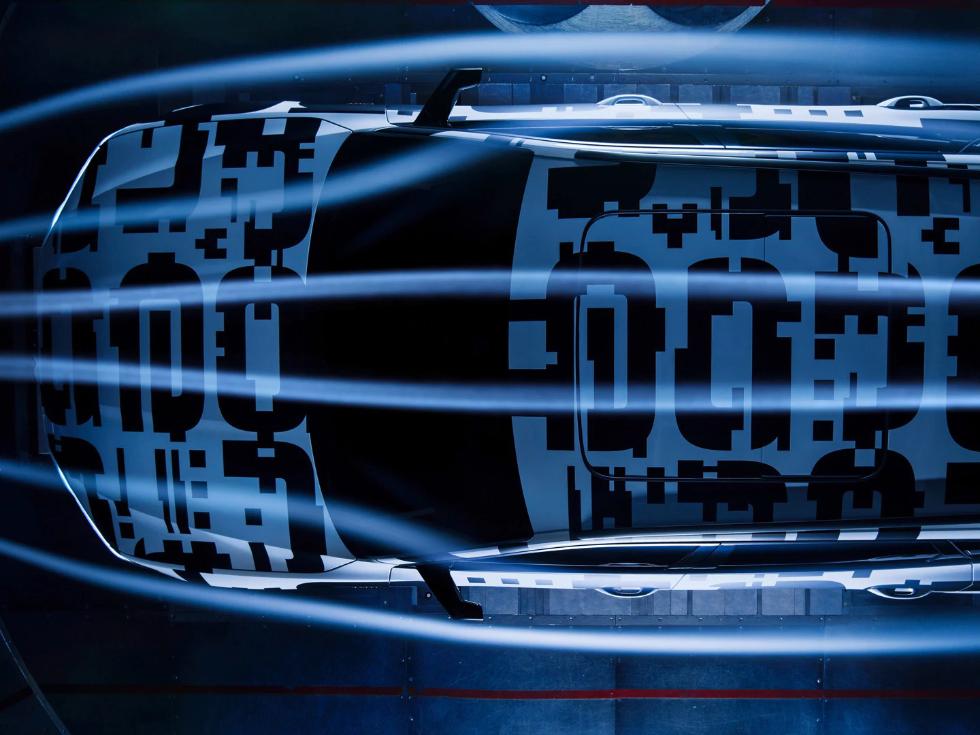

Electric cars: improving aerodynamics to increase range

Aerodynamics played a key role in the development of the e-tron, Audi’s first full-electric vehicle, even more than its actual weight. Aerodynamics development manager Moni Islam explains why this is the case.

What was the biggest challenge when developing the aerodynamics of the e-tron?

When we started designing the e-tron, we made a point of stating in the product specifications that it should be the most aerodynamic Audi model of all time in this vehicle class.

We had to bring all our knowledge and skills into this project.

How does an electric car’s aerodynamics differ from a “traditional� vehicle?

In general, you have less energy available overall while driving, so we need to optimise efficiency in every area, in every aspect. One in particular is air resistance when driving at constant speed, such as on freeways, where we need to ensure good range.

So do aerodynamics engineers have more influence on the development of electric cars?

Yes, because aerodynamics plays a crucial role in determining the range. The energy used to overcome air resistance cannot be recovered – unlike with vehicle acceleration.

From speeds of around 70 km/h, the rolling resistance of the tyres and the inertia take second place to aerodynamic drag, irrespective of the type of car.

Which areas of an electric vehicle offer more design freedom compared to a vehicle with an internal combustion engine?

Thanks to their large battery packs under the floor, electric vehicles have a very smooth and uniform underbody. This is the dream of every aerodynamics engineer. We’ve done all we can to make the shape of the body as streamlined as possible. The e-tron is also the first Audi model with an enclosed air flow, which is guided through the entire front end and back out through the underfloor.

What’s the most important component for the aerodynamics “package� of the Audi e-tron’s?

Definitely the virtual exterior mirror, and not just because it helps to improve the aerodynamics significantly, but because it’s also a component with a high symbolic value. It heralds a new generation of vehicles, with a radically different development approach.

Who had the idea - the engineers or the designers?

For years, aerodynamics engineers have looked forward to the day when it would be possible to dispense with exterior mirrors. The virtual exterior mirror concept for the Audi e-tron prototype was decided on relatively early on in the process. But who ultimately had the final idea, I can’t say. But it’s not important. What is important, even if it might seem an insignificant detail, is that this solution brings considerable advantages in terms of drag coefficient and extends the electric car’s range by around 2.5 kilometres.

How do improvements in aerodynamics benefit the customer?

As we said, range is closely related to aerodynamics. The e-tron concept is much more efficient than a conventional SUV of comparable size – in terms of range, that’s a gain of around 35 kilometres for the same energy expenditure.

When did you start working on the e-tron?

Back in 2013 we designed the initial concept, analysing the initial drafts alongside the designers and testing the first models in the wind tunnel.

Source: AUDI