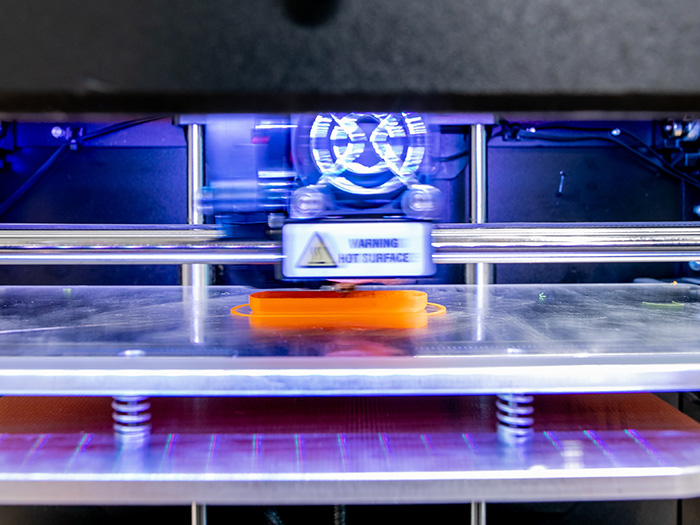

Creating customized tools with 3D printing

Audi started using a software that enables employees to design and then create tools for assembly and pre-assembly using 3D printing - quickly and without any prior knowledge.

Giving employees the chance to create the tools they need using 3D printing, and without the need for specific training, is the goal of a project run by the team of 3D printing specialists at Audi’s Böllinger Höfe site and trinckle, a Berlin-based company that develops innovative design software.

The Audi e-tron GT1 is the first vehicle for which 3D printing is an established part of preparations for series production. This means that all the tools for assembly and pre-assembly are developed much faster and are already in place at the start of production.

"Easy" software

With the newly designed software there is no need for the time-consuming process of manually sculpting models in CAD (computer-aided design) programs. That means workflows are much faster - using the new system cuts design time for tools by 80%.

“Our software makes the process of creating pre-assembly fixtures almost completely automated. It allows us to make the necessary tools quickly and flexibly and to respond to specific requests from the planners or our colleagues on the assembly line,” explains project manager Waldemar Hirsch, who is the head of the team of experts in 3D printing at the Ramp-Up and Analysis Center at Audi Böllinger Höfe.

The software is calibrated precisely to Audi’s needs and is also part of the process of digitalising production at the site.

Efficient processes

In the case of the Audi e-tron GT, which is set to roll off the assembly line at Böllinger Höfe together with the Audi R8 from late 2020, the 3D printing experts are working closely with their colleagues from the process and assembly planning and pre-series production teams.

Together, they have already started work on optimizing the assembly tools for the new workflows. “Collaborative design from an early stage enables us to optimize the process earlier as well. This means that all the necessary tools will already be available and calibrated when production of the e-tron GT begins,” says Hirsch.

Maximum precision

One of the 3D-printed tools is to be used in the pre-assembly of air-conditioning compressors and cooling lines. All components need to be aligned with each other with exceptional precision during assembly, something that has not previously been possible without a colleague’s help. Now, however, a custom-designed pre-assembly fixture with an integrated clamp holds all components in exactly the right position.

The materials used are designed to meet a wide range of requirements and satisfy the most exacting standards. In addition to the exceptionally stable tools containing glass fiber, the 3D printer also produces ESD (electrostatic discharge) materials. These are highly conductive and are used for electrically sensitive components.

Alongside the positive effects on operational processes, the development and use of this software represent further major strides in Audi’s digital transformation journey and are evidence of the changes taking place across all its production facilities as they move towards smart factory status.

The new software is currently installed locally and used primarily at Audi Sport GmbH at Böllinger Höfe, but there are plans to roll it out across the Volkswagen Group, which is already reaping the benefits of the expertise of the Neckarsulm site thanks to regular cross-brand communication. Another software application for smart management of 3D printing orders, also developed in Neckarsulm, is already in use at Audi.

1 vehicle not yet for sale

Source: AUDI AG