Software and digitalization at the heart of future car development

Digitalization is contributing to a radical change, transforming the car into a mobile software device that can be updated even after buying it, adding accessories and services. With the ACCELERATE strategy, Volkswagen is transforming itself into a hi-tech company, thanks to the key contribution of the division dedicated to Technical Development in Wolfsburg, capable of radically changing the design of new models.

The car at the centre of the digital ecosystem

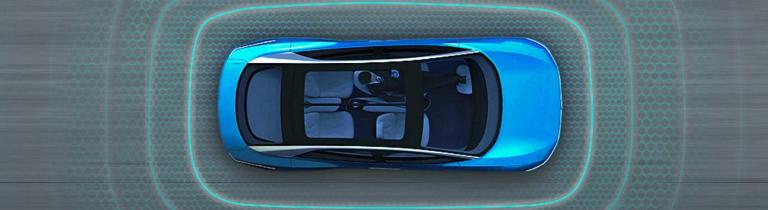

What does the car of tomorrow look like? Connected to its surroundings, safer thanks to assistance systems and able to keep on improving through digital updates. These will be the strengths of the Trinity project, a next-generation electric car to be produced by Volkswagen from 2026 that will include the technical foundations necessary for highly automated driving (Level 4 of autonomous driving).

Trinity will also mark the debut of the new modular SSP (Scalable Systems Platform) architecture, ready to be used in over 40 million vehicles and the starting point for a long series of models of all brands within the Volkswagen Group. The SSP is the result of the merging of the MEB and PPE e-platforms and as is already the case with the MEB, will also be open to third-party providers.

The car will be fully integrated into a digital ecosystem: a solution that not only changes the concept of mobility, but also contributes to the energy revolution and climate protection. One example? By feeding energy back into the home network thanks to bidirectional charging technology (Vehicle-to-Home) - as in the case of the Volkswagen ID.5 - the car turns into a power bank on wheels.

The central role of software

For automobile manufacturers like Volkswagen, digitalization is at least as big a job as electrification. While the Golf II hit the streets in the 1980s with 50,000 lines of programming code for its control units, current models can have up to 100 million lines: ten times as many as a smartphone. According to experts, this figure is set to triple in future fully connected, self-driving cars.

Constant updating

Updating the car after purchase is now possible, thanks to Digital Lifecycle Management (DLCM): while until now it was necessary to choose the equipment and accessories when signing the contract, this can now also be done later thanks to upgrades that can be purchased without having to visit a dealer. First finalised by Volkswagen in summer 2021, the OTA (Over-The-Air) update will become a constant on the brand's models and will open up new business scenarios. Talking about autonomous driving, in the future customers will also be able to purchase autopilot at a later date and for a limited period of time; an ideal solution for taking on longer journeys, for a holiday trip, for example.

Process optimization

As the pacesetter of the ACCELERATE strategy, Volkswagen's Technical Development (TE, from the German Technische Entwicklung) division is realigning its organisation, processes and working methods. The focus on individual parts is giving way to new components from software, as was previously the case in aircraft production. While in the 1990s cars were developed primarily with a component-oriented approach, with the growth of electronics, since the 2000s connectivity has played an increasingly important role.

In the future, the car will have to be seen as one of the systems within the overall customer ecosystem and be able to communicate seamlessly with all systems outside the vehicle, which is why the TE division is adopting a new mindset that emphasises user experience in all processes, with all functions able to interact seamlessly. For example, turning the car into a comfortable cinema when stuck in a traffic jam, with the car able to adapt the seating positions, air conditioning and interior lighting according to the customers' desires. All while offering maximum protection to the occupants even in the case of an accident.

Working agilely, develop faster

Even in the early stages of development, engineers consider the requirements of adjoining systems - whether charging or Smart Home - and incorporate them in their work. This new interdisciplinary way of working saves time and costs and increases efficiency by focusing on agile methods and organising tasks into sprints. In this way, a new vehicle project takes around 40 months of development instead of 54, as was previously the case.

It starts with a basic software architecture, which is being consistently developed in increasingly rapid evolution cycles. Production also benefits from this new working methodology: for example, the Trinity's production time target is only ten hours - roughly half that required for current cars.

More software, less hardware.

Today, the Volkswagen Golf has around 10 million configurations. Trinity will have just 140. This figure underlines how the hardware will be increasingly standardised and variants reduced, while the difference will be made by the software, thanks to the work done by CARIAD.

Using processes, methods and tools similar to those of the TE division, the Volkswagen Group's software house is aiming for greater integration of all systems.

The central role of training

The ongoing transformation is also changing the skills needed to make a car, with the focus shifting from the mechanical to the software component. This is why Volkswagen is investing in training the 12,000 employees in its Technical Development Division, 'moving' them from the world of internal combustion engines towards an electric and digital future.

The new Sandkamp Campus

At the heart of the transformation of the Technical Development division will be the new Sandkamp Campus. Under construction on the site of the Wolfsburg plant, it is set to become the world's most advanced automotive development centre.

Built with an investment of around € 800 million, it will house 4,000 employees and revolutionise normal company procedures by abolishing traditional barriers between departments and placing the User Experience (UX) division at the centre, which will oversee cooperation between the divisions. The overall aim will be to make approval and decision-making processes between departments short and efficient.

Source: Volkswagen - Shaping Mobility Hub

VGI | Responsible OU: VP | Creation date: article date | Class 9.1