BattMAN ReLife, the quick check system for lithium batteries

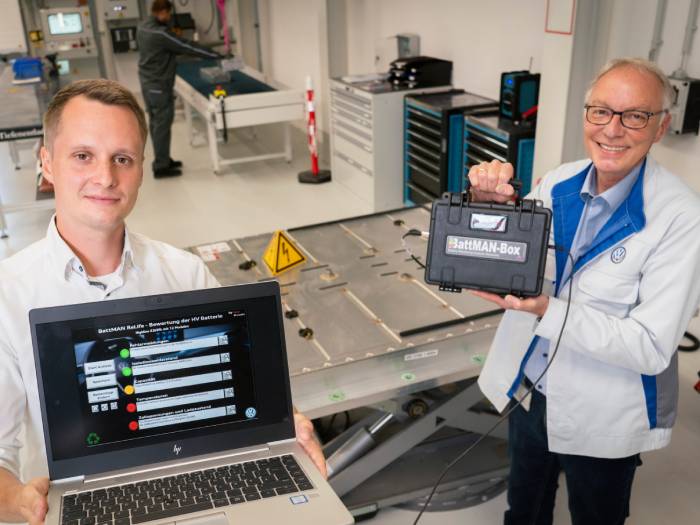

Volkswagen Group Components and Audi Brussels have developed the BattMAN ReLife quick-check system, which takes just a few minutes to assess the conditions of a battery and help set its further course.

One of the most common questions about electric cars is: what happens to the battery when an e-car has reached the end of its service life? There are several options, but before choosing one you need to check its state of health – and the BattMAN ReLife analysis software completes this task in few minutes. It is a quick check system that is already being used as a means of initial diagnosis in battery recycling at the Salzgitter pilot plant operated by Volkswagen Group Components.

The analysis of used lithium batteries

After the system completes its inspection and detects the remaining capacity of the accumulators, they can be partially or fully reused in other vehicles, used as mobile or stationary energy storage systems, or returned to cell production by means of an innovative recycling process.

The first version of the BattMAN (Battery Monitoring Analysis Necessity) software was developed by the Audi Brussels Quality Management department, with the aim of having a tool for quick and reliable analysis of the lithium-ion high-voltage batteries of the Audi e-tron. The software is already in use as a diagnostic tool for several brands of the Volkswagen Group.

Intelligent software: minutes instead of hours

BattMAN then underwent further development in cooperation with recycling specialists at Volkswagen Group Components, even before operations began at the pilot plant in Salzgitter.

After several months of programming and testing, BattMAN ReLife emerged as the new analysis solution that provides a reliable first assessment of a battery in just a few minutes, helping to set its further course. A process that previously took several hours.

The "traffic light

After plugging in the low-voltage connectors, the device first checks whether the battery is even able to communicate and transfer data. Then the system detects and displays any error messages, before moving on to the health status by evaluating parameters such as insulation resistance, capacity, temperatures and cell voltages.

"We are able to measure all a cell’s most important parameters. Then a traffic light system indicates the status cell by cell – green means a cell is in good order, yellow means it requires closer inspection, and red means the cell is out of order" explains Axel Vanden Branden, Quality Control Engineer at Audi Brussels.

Reconditioning or second life for batteries

If the battery is in good or very good condition, the first option is so-called remanufacturing, a process by which accumulators are reprocessed for further use - bearing in mind their market value - and put back into the value chain as spare parts for other electric vehicles.

If the battery's state of health is average or good, it receives its ‘second life’ and is reused as a mobile or stationary energy storage system, meaning it can be used for several years. There are various alternatives: from a flexible quick charging station to a mobile charging robot, from a driverless transport system to a forklift, but also from the domestic 'power bank' to an emergency standby power system.

Recycling lithium batteries

The third option is to recycle batteries that are in such a condition that they cannot be used for further applications. Here, through a series of mechanical processes, the batteries are dismantled to recover raw materials such as aluminium, copper, plastics and the so-called 'black powder', which contains the most valuable components: lithium, nickel, manganese, cobalt and graphite. Specialised partners separate them using hydrometallurgical processes and then transform them back into cathode material.

"We know that recycled battery materials are just as effective as new ones. So in the near future they will be used to supply our cell production activities" says Frank Blome, Head of the Battery Cell and System at Volkswagen Group Components. “The development of BattMAN ReLife is a great example of the successful cooperation between the various brands of the Volkswagen Group," emphasises Volker Germann, CEO of Audi Brussels.

Source: AUDI AG

VGI | Responsible OU: VP | Creation date: article date | Class 9.1