A miniature factory for testing out innovations

Over the last few months, a group of apprentices at Volkswagen headquarters in Wolfsburg have painstakingly built a facsimile miniature factory. In future, digital production processes will be tested here before they go into series production.

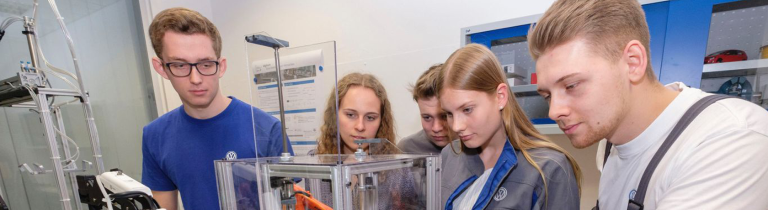

Lukas Kavemann stands, concentrating, at his touch panel. He is a 22-year-old mechatronics technician, and he is controlling the paint shop robot arm with a small screen, reminiscent of a tablet. He carefully lifts the rough chassis and immerses it in the dipping basin for cleaning. The paint shop is only one of several stations in the miniature factory that has been in the “digitum”, the new digitalization laboratory for technology planning in Hall 18, for a few days now.

There’s also the press shop, the body shop, assembly, and quality control. The individual stations are connected by two driverless automated vehicles. Everything just like the real Golf production a few metres away in Hall 54, –, just a few figures smaller. The 4 x 2 metre facility, reminiscent of a model railroad landscape, was built by 30 Volkswagen brand apprentices. “A cool project”, says Kavemann, while the blue-painted mini body drives through the light tunnel in the background. “It was fun being able to put what we learned during our training to practical use here”.

Five months, says trainer Lars Zander, is what it took from the first sketch to completion of the model. “It was very sporty. But the apprentices were highly motivated and did a great job”. The prospective industrial mechanics and mechatronics engineers installed several hundred metres of aluminium profiles and cables, half a dozen PLC controls, four electric cylinders and two robots for the miniature factory. All parts that are also used in the real factory.

In future, the miniature factory will primarily be used by the Technology Planning department, which is responsible for the digitalization of production. Currently, digital innovations are tested either during the non-production period or during operation, which is problematic. “Until now, we’ve lacked a test field where we could just try out different planning scenarios with no need to worry”, explains Dirk Voigt, Head of the department. The miniature factory will be perfect for this role: “What works here can be integrated much more easily into serial operation later on. And maybe even more importantly, errors that occur here can be corrected before they crop up later on the line”.

Source: Volkswagen